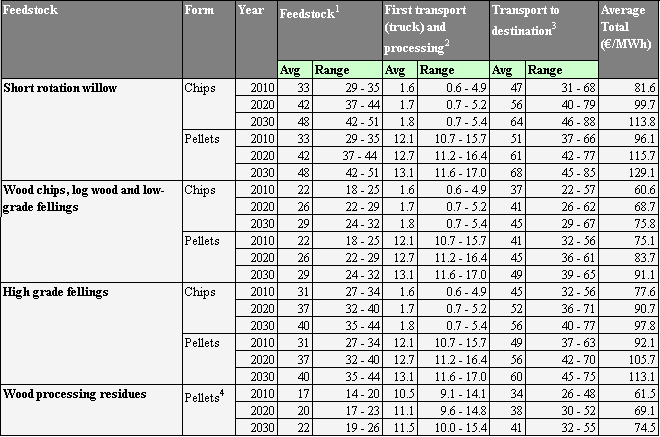

A key consideration in the viability of biomass energy is its cost, most of which is incurred in the course of transport. This is particularly true in developing countries which often lack sufficient infrastructure. A report supported by Intelligent Energy-Europe titled “Long Term Potentials and Costs of RES; Part II: The Role of International Biomass Trade” estimates average costs for various feedstock categories in Europe, with forecasts given out to 2030.

Biomass supply costs (Euros per MWh)

The study shows the disproportionately high cost of transport, even within relatively developed Europe. These expenses often restrict developing world biomass energy systems to local sources of feedstock, and are the reason that facilities which cater to export markets must produce in large quantities near the coast to make trade worthwhile. Infrastructure improvements in developing countries are helping to mitigate these problems, albeit incrementally, to increase the viability of biomass and its trade.

Also of note from the study: In addition to lower processing costs, woodchips are less expensive to transport due to their higher bulk densities. A typical cubic meter of woodchips weighs 610 kilograms, in comparison to 240 kilograms for the same volume of wood pellets. The study shows a clear advantage in terms of Euros per MWh for wood processing residues such as sawdust.

See the Intelligent Energy-Europe study for a more detailed analysis of transportation costs.

———–

1) Costs to the farm gate, including cultivation and harvest.

2) Costs of processing, to include chipping or pelletization, as well as truck transport to the collection point.

3) Intra-European transport, based on the lowest cost routes between countries, with cost dependent on distance and transport method (ship, rail, and/or truck).

4) Inclusive of sawdust.