Brick-and-mortar Factory With The Latest Manufacture Technology

GEMCO knows that technology defines the productivity. We have established our own Research & Development Department, and always keep the sensitivity to the latest manufacture technology around the world. Right now, Gemco pellet equipments are manufactured by the technologies such as: forging and stamping, vacuum heat treatment, carburizing and quenching, vacuum hardening, crack detection, etc. More importantly, real factory manufacture means no crazy mark-up.

forging and stamping station

vacuum hardening station

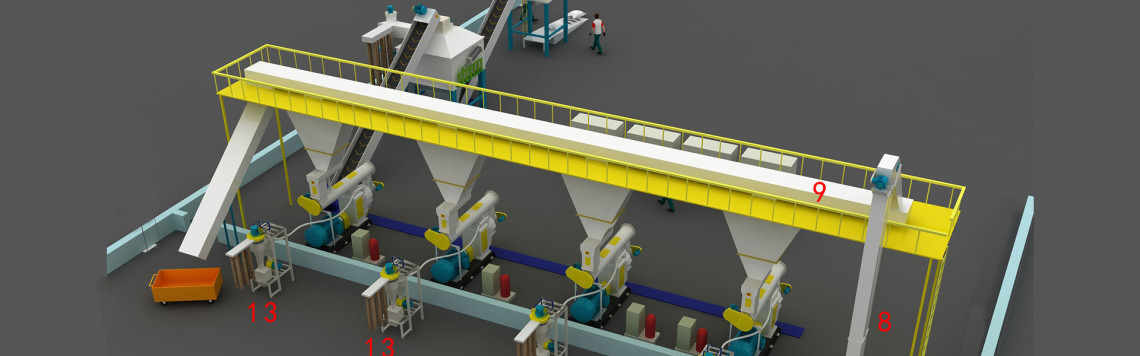

Project Design

There are so many successful pellet line projects around the world, which is accompanied by Gemco . So before you try to establish your own pellet production line, Gemco will listen to your needs, your budget critically. And with all the information, Gemco will help you to design your plant and choose the most suitable equipments for you.

pellet plant design

Onsite Installation And Operation Training

GEMCO offers onsite installation with professional technicians and project manager and translator (if necessary). Our team will work together with clients to finish installation as scheduled. After that, real commissioning will be carried out as per clients requirements. We also help clients to do troubleshooting for each parts. During this process, we teach the operators from clients to learn the basic operation skills.

pellet plant installation

After Sale Service

Please be rest assured that GEMCO does has after sale service. We have build many wood pellet plants and biomass pellet plants over the world. How could a company with no after sale service did that? GEMCO offers you 24*7 email, skype, phone communication, needless to say, spare parts supply, which is one of our best strength.