PELLET MACHINE

GEMCO ring die pellet mill introduction

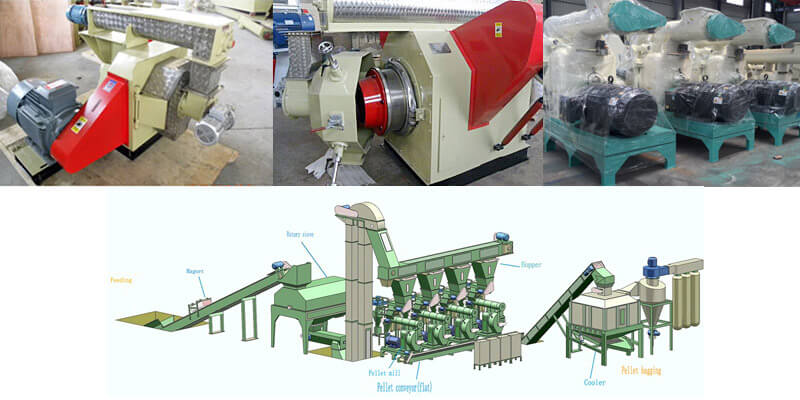

Normally, there are two main kinds of pellet mills, ring die pellet mill and flat die pellet mill. For ring die pellet mill, there are horizontal type and vertical type. Unlike flat die pellet mill, which is used mainly for household and small scale, the ring die pellet mill is a must-have equipment in a pellet plant. Take wood pellet plant as an example, typically, you will need one or more ring die pellet mill (depending on the amount of raw material you are dealing with), a hammer mill or wood chipper for resizing raw material in large pieces, a pellet cooling system, a packing machine and other necessary types of equipment. Among all the pieces, ring die pellet mill is the key to success for your pellet plant. Having said that, it doesn’t mean that each ring die pellet mill for sale in the market is suitable for you. You have to make your choice.

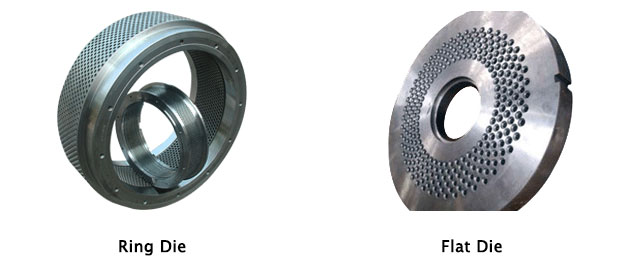

Something About Pellet Mill Dies

The “ring die” in a ring die pellet mill is the first and the most important part you shall exam while buying a pellet mill. For a wood pellet plant running 10 hours a day, the ring die is the most worn part because it finishes most of the jobs of a ring die pellet mill. Which means a quality ring die pellet mill comes with a quality ring die. The “die” is a metal with multiple holes on it, and during the process, the raw materials are heavily pressed to pass through the holes so that it can be pelletized. While the flat die is a flat metal plate. This picture shows the difference below:

GEMCO BPM Ring Die Pellet Mill

Gemco ring die pellet machine BPM series are the most popular large pellet machines according to our customers’ feedback. It covers both medium scale and large scale wood pellet production requirements. Also, it provides different solutions for wood pellet production. For example, with 1-2 ton/h wood pellet production needs, you can either choose three or four BPM35 pellet mill to connect them together, or you can buy 1 BPM420 or BPM508 pellet mill to match the requirements. Therefore, wood pellet manufacturers can choose the pellet mills more freely based on their own considerations, such as budget, their business development directions, etc.

Gemco BPM Ring Die Pellet Machine Specifications

| Model | Image | Capacity | Size (mm) | Power (Kw) | Net Weight (Kg) |

| BPM25 ring die pellet mill |  |

200-250kg/h | 1700x1200x1000 | 22+0.75+0.37 | 800 |

| BPM35 ring die pellet mill |  |

500-800kg/h | 2150x1950x1900 | 30*2+0.75+0.75 | 2200 |

| BPM420 ring die pellet mill |  |

1.2-1.5 t/h(sawdust) | 2500x1100x1900(2300) | 90(main motor) | 3000 |

| 1.5-2.0(stalk) | 1.5(feed machine) | ||||

| 2.2(conditioner) | |||||

| BPM508 ring die pellet mill |  |

1.5-1.8 t/h(sawdust) | 2800x1100x1900(2300) | 110(main motor) | 3700 |

| 2.0-2.5(stalk) | 1.5(feed machine) | ||||

| 2.2(conditioner) |

Gemco BPM Ring Die Pellet Machine Features

- With the technology of aerodynamics, Gemco ring die pellet mill has successfully reduced the pellet machine chamber temperature. Therefore, during the pelletizing process, the temperature of pellet machine chamber will stay about 90°C. So, the continuous operation of Gemco ring die pellet mill is ensured.

- There is a timing function of Gemco wood pellet machine feeder, which can control the feed speed, and avoid pellet mill ring die blockage.

- Gemco wood pellet machine maximum its capacity by adding a force pellet machine feeder. And all the wood pellet machine components are made of quality stainless steel.

- Gemco engineers have improved our screw conveyors for industrial wood pellet machines, to provide our clients better adjustment of wood material feed speed.

- Gemco wood pellet mills use gears with high precision.

- Gemco wood pellet mill ring die is made of quality steel and forged. Typically, Gemco pellet mill ring die can process 800-1000MT wood pellets.

Advantages of GEMCO ring die pellet mill

- Large capacity: Gemco ring die pellet mill is specialized in large-scale business, such as industrial biomass pellet production. Its large capacity range covers from 200kg/h to 2.5 ton/h. Larger capacity pellet plant is realized by connecting several ring die pellet mills in parallel, in that case, you can reach a capacity up to 30 ton/hour.

- High density: compare to the flat die pellet mill, the pressure of the ring die pellet machine is much higher so that the pellet it makes has a higher density and smoother surface. The higher the density is, the higher combustion value it has.

- Cost-efficient: our ring die pellet mill uses the German bearings and oil seal so that it is much more stable than others. Also, compare to the small pellet mill, during the pelletizing process, both edges move the same distance, so the roller and die wear evenly, it can save the replacement part.

- make pellets from different raw materials: GEMCO understands that wood pellets are the most required product. Therefore we build our ring die pellet mill optimal for any wood species, no matter what you have: hard wood, soft wood, logs, branches, bark, sawdust, wood shavings EFB, etc. All material is practically proven by our clients. You may check our successful wood pellet plant projects here. Besides that, GEMCO ring die pellet mill is also good at making biomass pellets, which technically is easier than wood pellets, for the following materials: grass straw, peanut shell, rice husk, cotton stalk, EFB fiber, to name but a few. If you have material that you don’t know if it can be pelletized, contact GEMCO, we also provide FREE material test service for you.