Commercial Wood Pellet Mill For Sale

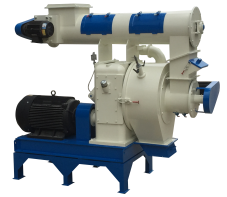

GEMCO commercial pellet mill

Introducing GEMCO Commercial Vertical Ring Die Pellet Mill

The new type vertical ring die pellet mill developed by GEMCO is intended to provide the customers with a modern solution for large-scale pellets production purpose from wood or other biomass material.

It features in robust shaft, powerful output, stable operation, low failure rate and less production cost.

The specifications of GEMCO commercial pellet mills

| Model | Power (KW) | Pellet size (mm) | Capacity (wood) | Outer dimension (mm) | weight (KG) |

| HSL508-3-55KW | 55 | 6-12 | 0.8 | 2133*920*1389 | 2586 |

| HSL508-3-75KW | 75 | 6-12 | 1-1.2 | 2400*1300*1800 | 2908 |

| HSL510-3-90-110KW | 90-110 | 6-12 | 1.5-1.8 | 1800*1100*1700 | 3780 |

| HSL630-3-132KW | 132 | 6-12 | 2-2.2 | 1800*1100*1700 | 5600 |

8 reasons why you should choose GEMCO commercial pellet mill

-

-

- The gearbox has 3 transmission ratios for your choice: 1:18, 1:16 and 1:20. High quality carburized and quenched alloy steel is used for the gearbox so that the precise transmission is guaranteed. Top brand FAG bearing is attached.

FAG bearing for pellet mill

- Simens Y315M-4-V1-132KW motor is inside.

- External circulation cooling (air or water) is used for the gearoil of main transmission box. The working temperature is as low as 40-50 Celsius degree.

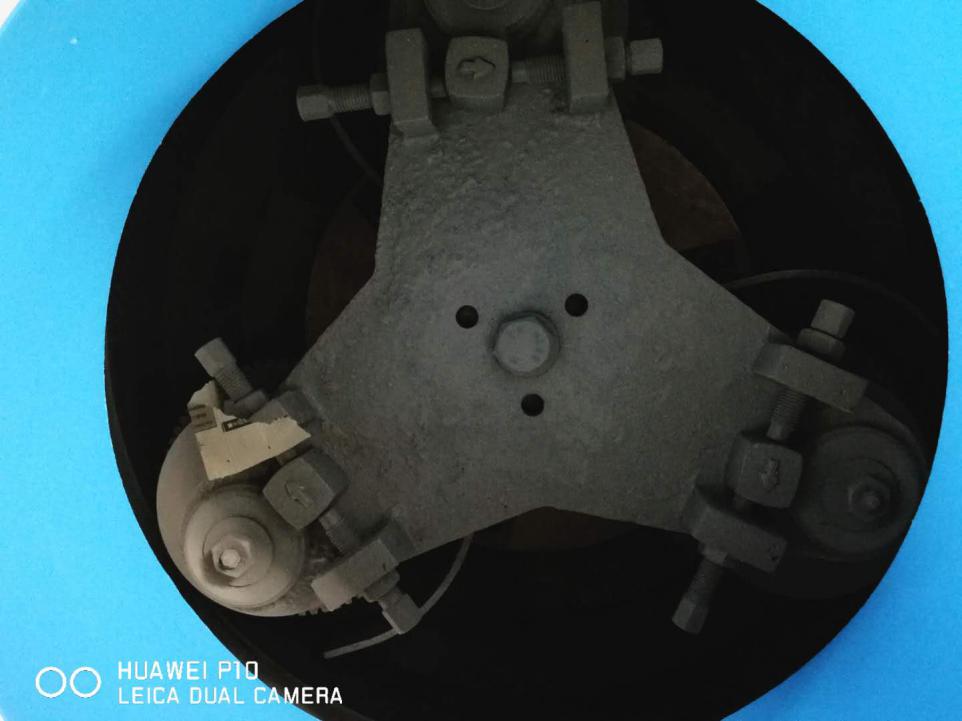

- A 3-roller assembly is used for higher pellets output.

3 rollers structure

- The roller is specially designed for longer duration with less wearing. Frequent lubrication is not necessary anymore.

the roller

- The transmission gearbox is lubricated in multiple places and is cooled down in circulation. The main shaft is lubricated separately by thin oil instead of grease oil which causes aging and carbon deposition.

lubrication system

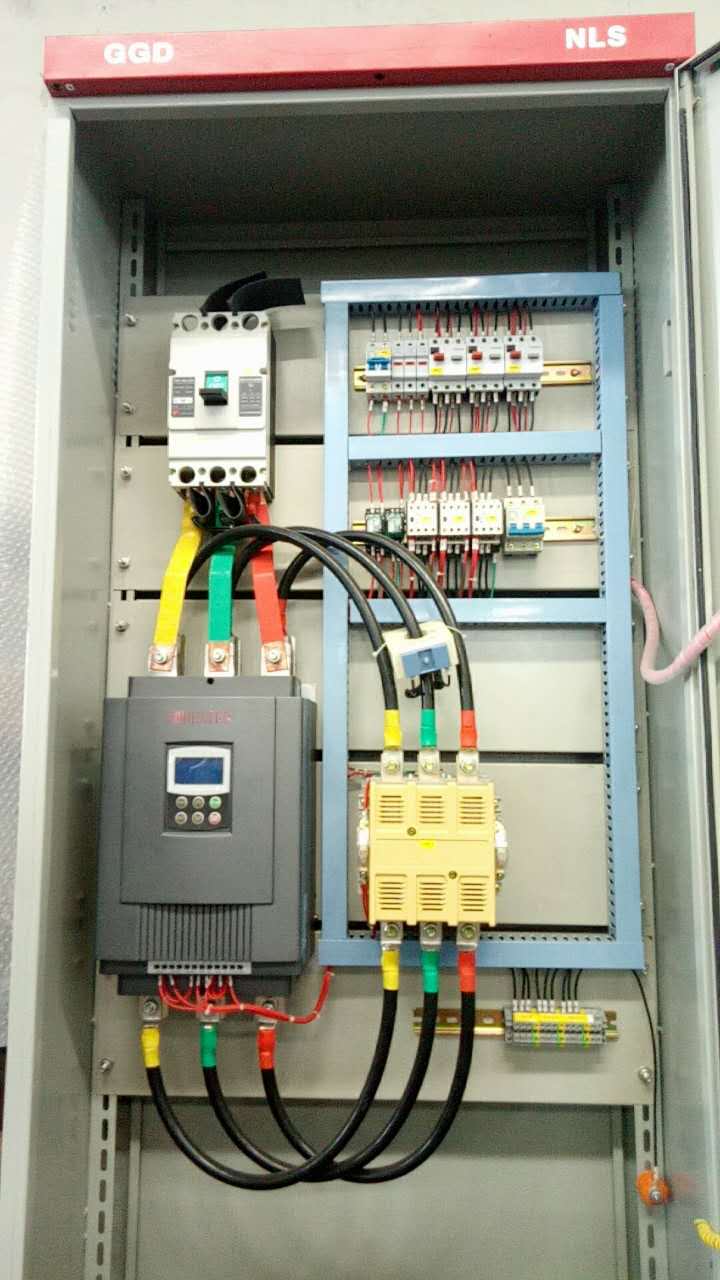

- For electric control unit, the upgraded high-power soft starting method is used, which is just suitable for the vertical ring die type.

soft starting control unit

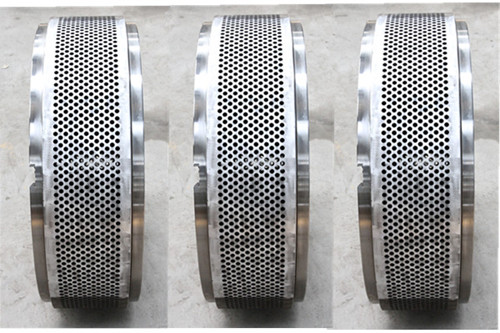

- The stainless steel ring die can be customized as per the client’s requirements and product ranges.

the ring die parts

- The gearbox has 3 transmission ratios for your choice: 1:18, 1:16 and 1:20. High quality carburized and quenched alloy steel is used for the gearbox so that the precise transmission is guaranteed. Top brand FAG bearing is attached.

-

How to choose among small pellet mill, regular ring die pellet mill and vertical ring die pellet?

As a professional pellet mill manufacturer, GEMCO produces small pellet mills and ring die pellet mills. For ring die pellet mill, there are the regular type (horizontal type) and the vertical type. Each type has it’s own purpose. When choosing the pellet mills, the first question to ask yourself is how many material do you have or how many pellets do you plan to make every hour. If you have a small capacity requirement (less than 0.5 ton/h), and the production will not last all day long, then a small pellet mill is all you need.

small pellet mill

ring die pellet mill (horizontal type)

ring die pellet mill (vertical type)

If you have a large capacity requirement, you probably need the machine to run 20 hours per day, if this is the case, choose ring die pellet mill. Here comes the second question: the horizontal type and the vertical type, which is the better choice for me?

To answer this question, read below the information about the common and the differences between the two types.

The common: both horizontal type and vertical type are ring die pellet mill, meaning that they have the same basic working principle, as shown in animation below:

ring die pellet mill working animation

The difference: the key difference lies in the appearance of the ring die. For the die part of vertical pellet mill, there are two rows of pellet holes in parallel, while for the die part of the horizontal pellet mill, there is only one row of pellet holes, but much wider. Please be noted that the hole quantity can be customized based on the capacity and the property of the raw material. However, there is actually no substantial difference for both types of die parts. To choose which one is suitable for you is solely by your own judgment. As the size and appearance of the pellet mills of both types are quite different, you may make this decision combination by the layout profile of your production site.

ring die of vertical pellet mill

ring die of horizontal pellet mill

Besides, both vertical and horizontal ring die pellet mills have more than 1 models for their own, to make comparison easier for you, please check the table below.

| vertical pellet mill | horizontal pellet mill | |||||

| HSL508-3-55 | HSL508-3-75 | model 420 | model 508 | model 510 | model 510 | |

|

|

|

|

|

|

|

| power (kw) | 55 | 75 | 90 | 110 | 90 | 90-F |

| dimension

(mm) |

2133*920*1389 | 2400*1300*1800 | 2906*1153*2414 | 3088*1135*2420 | 2682*1322*2656 | 2682*1322*2656 |

| weight

(kg) |

2586 | 2908 | 3326 | 3778 | 3900 | 3900 |

| die inner diameter

(mm) |

¢508 | ¢508 | ¢420 | ¢508 | ¢510 | ¢510 |

| die material | stainless steel / alloy steel | stainless steel / alloy steel | stainless steel / alloy steel | stainless steel / alloy steel | stainless steel / alloy steel | stainless steel |

| rollers | 3 | 3 | 2 | 2 | 2 | 3 |

| roller material | 20crmnti | 20crmnti | 20crmnti | 20crmnti | 20crmnti | GCR15 |

| grease type | high temperature | high temperature | high temperature | high temperature | regular | regular 2# |

| filling frequency | each shift | each shift | 2h | 2h | each shift | each shift |

| designed capacity (kg) | 600~700 | 1000~1200 | 1000~1300 | 1300~1800 | 1300~1800 | 1500~2000 |

| pellet diameter (mm) | ¢8~¢9 | ¢8~¢9 | ¢8~¢9 | ¢8~¢9 | ¢8~¢9 | ¢8~¢9 |

| gearbox lubrication | nonstop | nonstop | automatic | automatic | automatic | automatic |

| gearoil | 32# | 32# | 32# | 32# | 32# | 32# |

| gearbox cooling | external air cooling (optional) | external air cooling (optional) | / | / | external air cooling (optional) | external air cooling (optional) |

| main motor speed | 65 | 65 | 140 | 140 | 138 | 138 |

| forced feeding | / | / | 1.1KW | 1.5KW | 1.5KW | 1.5KW |

| conditioner | / | / | 2.2KW | 2.2KW | 2.2KW | 2.2KW |

| transmission | belt+gear | belt+gear | gear | gear | gear | dual gear |

| feeding water content (%) | 13-17 | 13-17 | 13-17 | 13-17 | 12~22 | 12~22 |

| pellets conversion | 91% | 91% | 91% | 91% | 91% | 91% |

| pellets formation | 98% | 98% | 97% | 97% | 97% | 97% |

| pellet length (mm) | 10~35 | 10~35 | 10~35 | 10~35 | 10~35 | 10~35 |

| rice husk capacity (kg/h) | 500 | 900~1000 | 700 | 1000 | 1300 | 1500 |

| wood capacity (kg/h) | 700 | 1000~1200 | 1000 | 1300 | 1300~1500 | 1500~2000 |

| crop straw capacity (kg/h) | 500 | 700~800 | 1000~1200 | 1500~2000 | 1500~2000 | 2000 |