Biomass pellet fuel is a typical solid biomass fuel which shows the advantages such as highly efficient, clean, easy to burn and carbon zero emission. Biomass pellet can be used in both civil and industrial fields such as cooking, heating, boiler combustion and electric generation. It is one of the famous substitutes of coal in the world. But the poor quality biomass pellet has high ash content and high alkali metal content, which may cause slag bonding, alkali and chlorine corrosion or serious fly ash problem in the combustors during biomass pellet combustion.

Therefore, to analyze biomass pellet combustion characteristic such as ignition property, combustion efficiency, pollutant discharge and ash properties, will help the biomass pellet manufacturers to produce suitable biomass pellet to supply the different markets.

Test Material of Biomass Pellet Combustion Property

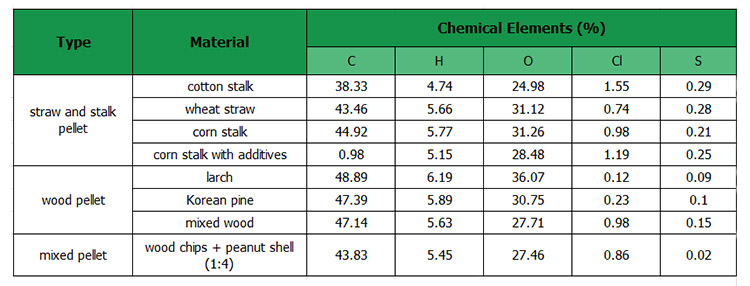

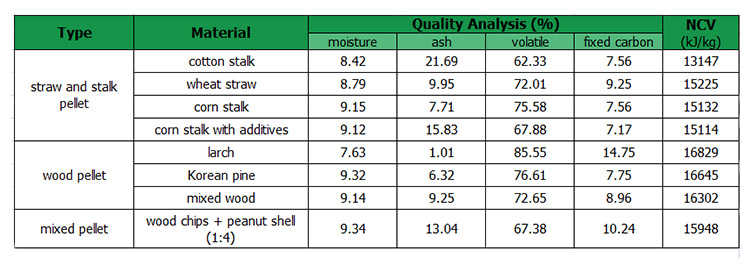

All the biomass pellets used for the test is made by a professional biomass pellet plant. In order to compare the different material biomass pellets combustion characteristics, we have chosen eight typical biomass pellet fuels, which include four types of straw and stalk pellet fuels (cotton stalk pellet, wheat straw pellet, corn stalk pellet, corn stalk pellet with additives), three types of wood pellet fuels (larch pellet, Korean pine pellet and mixed wood pellet), and a types of biomass pellet fuel which is made from wood chips and peanut shell, and the quality ratio of wood chips and peanut shell is 1:4. All the biomass raw materials has been pelletized into biomass pellet with the diameter of 8mm, and length between 10-30mm. The pellet density is about 1.2g/c.

Table 1 Ultimate analysis of eight types of biomass pellet fuels

Table 2 Proximate analysis and heat value of biomass pellet fuels

Test Instrument And Devices of Biomass Pellet Combustion Property

Test instrument

The test instrument includes a GJ-2 sealed sample preparation comminuter, a XL-1 high temperature oven, a VarioEL elemental analyzer, a VISTA-MPX inductively coupled plasma optical emission spectrometer (ICP), a BSA223S-CW analytical balance, a PL2002 electronic balance, a SZ11-4 automatic sieving machine, a KM9106 flue gas analyzer, a 101.1A electric thermostatic drying oven, a ZDHW-5 automatic high precision computer calorimeter, a HR.45 intelligent ash fusion point determination meter and so on.

Test device

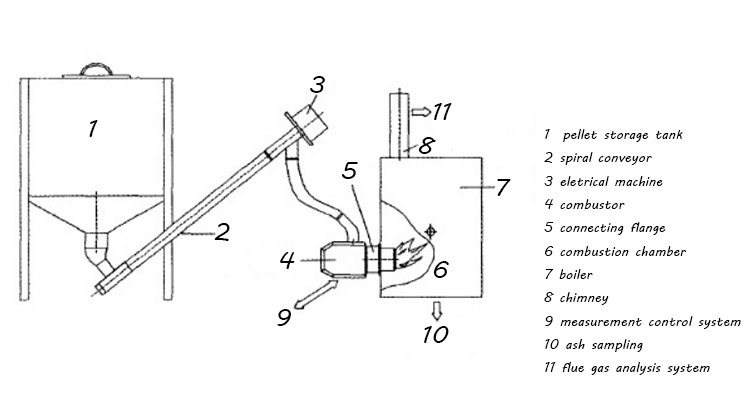

The complete device for the test is shown as the following picture (Table 3). The complete system consist of the pellet storage tank, spiral conveyor, combustor, boiler, flue gas analyze system and the measurement control system. We use the PelleX automatic biomass pellet combustor which is imported from Sweden, the thermal output of the combustor is 10-25kw, and the combustion efficiency is about 90%. The power consumption of ignition is 400w, and the power consumption of operation is 40w.

Test operation procedure: when we start the device, the spiral conveyor will transport the biomass pellet to the combustor. Then we should open the operation switch, the combustor starts, and the biomass pellets has been fed in the combustor. When the biomass pellets reach the start quantity, the combustor ignites. After the start-up, the air blower starts, and the pellet firing area enlarges, the spiral conveyor keep on feeding biomass pellets. After the fire is stable, the test device goes into the pre-operation stage. After the combustion performance is stable, the test device goes into the operation stage. The air blower runs at full speed, the spiral conveyor feeds biomass pellet at the specified speed, and the combustor operates at full power. When the outlet water temperature of the boiler is about 5℃ lower than the pre-set temperature, the combustor operates at low power, the biomass pellet feeding rate stays around 65%, also, we should lower the speed of the air blower. When the outlet water temperature reaches the pre-set temperature, the flame will be knocked down, the spiral conveyor stops, and the air blower will keep on working for a certain time and then stops, and the combustor is at the stop stage. When the outlet water temperature of the boiler is lower than the pre-set temperature, the combustor starts again.

There is a controller of the combustor, which can monitor the complete working process of the combustor automatically. The controller can monitor the start and stop of the combustor, adjust the feeding quantity, feeding speed and supply air rate, and set different start temperatures and stop temperatures. Moreover, the controller can show the different working stages of the combustor, and the overheating protection, ignition failure, and breakdown during combustion.

Table 3 Schematic of the experimental burning system

Test Method of Biomass Pellet Combustion Property

Before the test, all the biomass pellet should be taken samples to run the proximate analysis, ultimate analysis and heat value test. After the test, we should weigh the weight of ashes and slags and take samples of the ashes and slags to analyze its melting characteristics and chemical components. The biomass pellet quantity to start the combustor is 230-250g, the feeding speed is 4-4.5kg/s, each types of biomass pellet should be test 3 time, and average the results.

Ignition property: it is used to measure the firing time of the fuel. Use a stop watch to record the time from start the combustor to successful ignition.

Emission property: flue gas analyzer can record and analyze the flue gas in real time. The flue gas sampling point is right at the connect point of the chimney and the boiler, and is 200-250m away from the boiler.

Slagging rate of the ashes: take one types of the testing biomass pellets, burn it in the combustor, control the feed quantity, supply air rate and other testing conditions. When the combustor stops, take out and weigh the ashes, record the ashes’ weight as M. Then pick up the slags larger than 6mm in the ashes and weigh the slags weight as m. Therefore, the slagging rate of the ashes is m/M╳100% .