Biomass Pellet Background

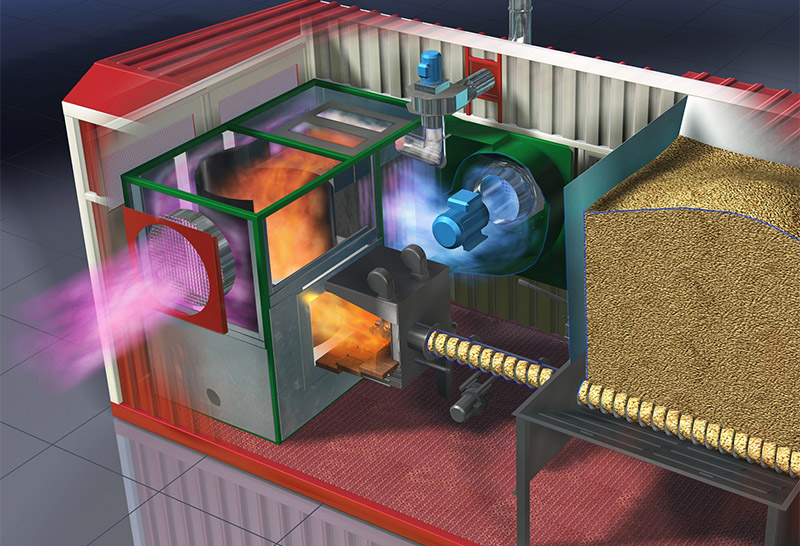

Biomass pellet is a new type of renewable fuel which is made of high quality wood chips and corn stalks. The wood materials must go through several processes such as crush, mix, compress and drying to become biomass pellets fuel which can be burned directly.

Normal biomass materials have the disadvantages such as loose, low density, and low thermal value. Therefore, it is very difficult for us to use biomass materials as the burning fuel directly. Using the pellet compression technology, biomass pellet plants make the loose biomass material into solid biomass pellets. The development of biomass pellet not only solve the difficult burning problem of biomass materials, but also improve the combustion performance of wood chips and corn stalks.

Biomass pellet manufacture technology makes the loose biomass materials into compressed high density biomass pellets which maintain the pellet density over 10 times more than normal biomass materials. Moreover, the biomass pellets are easy to store and transport, and the flue ash emission after combustion is much lower than coal, which makes biomass pellets a high quality combustion fuel for all kinds of burning and heating purposes.

Biomass Pellet Market Analysis

As a new type of renewable solid fuel, biomass pellet be can be used in many different markets to replace fossil fuels.

Biomass pellet application in thermal power market

Biomass pellets can be used as the mixture burning fuel for thermal power plants. The majority of British thermal power plants has already adopt biomass pellets as their burning fuels, such as the Drax thermal power plant in North Yorkshire. In America, the contribution of biomass pellet fuel to the thermal power market in 2010 is $45 billions, and this number will increase to $53 billions by the year of 2020.

Biomass pellet application in residential heating purpose

In rural areas, most of the stoves use fire wood as the burning fuel. As we all know, the burning efficiency of fire wood is low, and it is hard to store. Moreover, it is also difficult to develop a device that can control the fire wood quantity during combustion period and feed in fire wood automatically. But if use gas and electricity as the burning fuel, the cost is much higher than fire wood. This conflicted situation gives biomass pellets a broad market prospect as the biomass pellets maintain the advantages as high burning efficiency, easy to store, competitive price and so on.

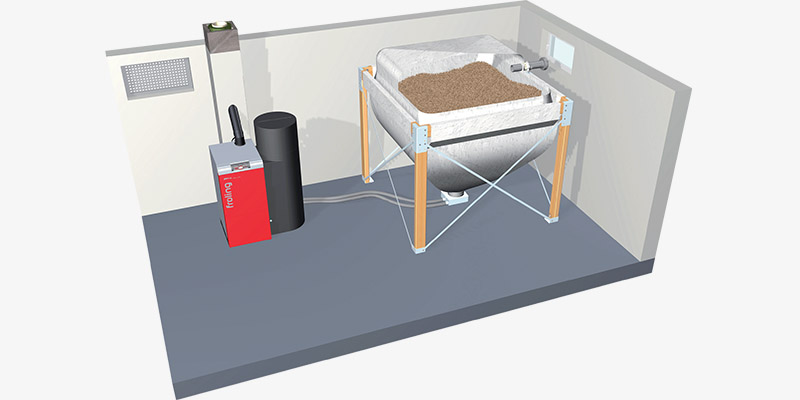

Expect for stoves, biomass pellet can also used as the burning fuel for residential heating system and central heating system. Biomass pellet heating system has been highly recommended in North European countries such as Demark and Hungary. Using the pre-setting mode, this type of biomass pellet boiler can realize the automatic operation continuous over a week. It can control the temperature, feed in biomass pellets, supply the hot water automatically.

Biomass pellet application in industrial boiler

In China, there are over 600 thousand industrial boilers. Among these industrial boilers, there are about 120 thousand oil burning boilers and gas burning boilers, which is 20% of the total industrial boilers. Like all the other countries, China also has abundant biomass sources which is about 3 billion ton per year, which is equal to an equivalent of one billion petroleum per year. This is three times of the current petroleum consumption in China.

Hypothetically, if we convert 10% of the oil and gas burning boilers into biomass pellet boilers, and each industrial boiler capacity is 10t/h, then we will use 200 million ton biomass pellets per year, which means we can save 70 million ton petroleum per year.

The advantages of convert the industrial boilers into biomass pellet boilers are placed as follow:

- Under the same thermal value, use biomass pellet is ¥160 cheaper per ton than coal. Therefore, we can save ¥76 million fuel fee per year. Compare to oil fuel, we can save 20% of the total fuel fee.

- The GDP energy consumption per unit is nearly zero, as biomass pellet is renewable fuel, it is no need to included in the energy consumption.

- Using biomass pellets can increase the thermal efficiency and save the fuel cost. If we use biomass pellet for industrial boiler, the thermal efficiency of boilers is 10% higher, which can save 3.6 thousand ton coal per year, and the fuel cost is ¥44 million lower than before.

- Using biomass pellets can save the desulfurization fee and dust removing reformation fee. The desulfurization fee for per ton sulfur dioxide is ¥1000, each year, the desulfurization fee is ¥780 thousand. If we use biomass pellet boilers, ¥780 thousand can be saved per year.

Biomass pellet application in farm

Nowadays, many countries are trying to develop the system that use biomass pellet as the fuel for the air heating system for grain drying. As the raising agriculture products price, not only the biomass pellet air heating system, but also the biomass pellet central heating system for farm is more and more popular.