What is Sugarcane Bagasse?

Sugarcane, or sugar cane, is a well known economic crop with a sweet taste and an important application. Due to its application , the sugarcane can be divided into two types, the chewing sugarcane and the one to be the raw material of sugar industry. The chewing sugarcane is the one to be tasted freshly, this kind of sugarcane remains a thin skin, less fiber content, a crisp stem, medium sugar content and juicy taste. Otherwise, the sugarcane for sugar production normally has a high sugar content, hard skin and coarse fiber which taste badly. Sugarcane is an annual or perennial herb mainly grown in tropics and subtropics. The origin of sugarcane may be New Guinea or India, and then spread to South Pacific.

Bagasse is the fiber residue after the sugarcane has been crushed to extract the juice in the sugar mill. Each 10 tons of sugarcane can produce 3 tons of wet bagasse. The wet bagasse has a moisture content about 40%-50%, therefore the plants usually store them for further drying process. To be a fiber material, the sugarcane bagasse can be used to be a raw material of biomass pellet in the pellet plant for heat and electricity generation, or to be a substitute for wood in pulp & paper industry. Besides, there are also some board mills use the bagasse to be a substitute for plywood.

The Sugarcane Bagasse Source in the World

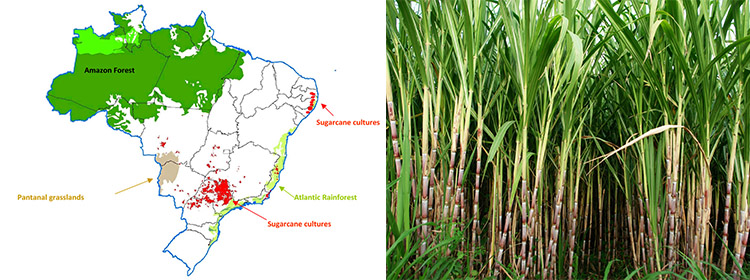

To find the sugarcane bagasse source, the first thing is to find the well developed sugarcane origin or large sugar mills. Sugarcane is mainly distributed between 33 degree north latitude and 30 degree south latitude. From 1996 to 2002, the planting area of sugarcane is about 20 million hectares (about 48 million acres) in the world. The top 3 countries who hold the largest sugarcane planting area are Brazil, India, and China. The annual sugarcane planting area of the top three countries are 4.9 million hectares, 4.1 million hectares and 1.2 million hectares. Besides, there are also some other sugarcane superpowers, such like Cuba, Thailand, Mexico, Australia, The United States, Indonesia, and South Africa. As we all know, sugarcane is the main raw material to make sugar, so these countries also hold a strong sugar production industry for both domestic and oversea sugar market.

Top 10 countries for sugarcane planting(area unit: hectare)

| 1996 | 1997 | 1998 | 1999 | 2000 | 2001 | 2002 | average | % | |

| Brazil | 4,750,000 | 4,814,000 | 4,986,000 | 4,898,667 | 4,846,000 | 4,973,333 | 5,061,333 | 4,904,000 | 25.16 |

| India | 4,150,000 | 4,170,000 | 3,940,000 | 4,054,667 | 4,220,000 | 4,296,667 | 4,100,000 | 4,133,333 | 21.21 |

| China | 1,243,333 | 1,108,000 | 1,186,667 | 1,042,667 | 1,188,667 | 1,281,333 | 1,240,000 | 1,184,667 | 6.08 |

| Cuba | 1,244,667 | 1,246,000 | 1,048,667 | 996,000 | 1,040,667 | 1,007,333 | 1,007,333 | 1,084,000 | 5.56 |

| Thailand | 985,333 | 980,000 | 917,333 | 945,333 | 922,000 | 850,000 | 850,000 | 921,333 | 4.73 |

| Mexico | 633,333 | 614,667 | 630,667 | 643,333 | 618,000 | 624,000 | 615,333 | 625,333 | 3.21 |

| Australia | 383,333 | 401,333 | 420,000 | 414,000 | 419,333 | 411,333 | 417,333 | 409,333 | 2.1 |

| America | 360,000 | 369,333 | 383,333 | 402,000 | 418,000 | 416,000 | 415,333 | 394,667 | 2.03 |

| Indonesia | 430,667 | 384,000 | 405,333 | 391,333 | 405,333 | 406,667 | 345,333 | 395,333 | 2.03 |

| South Africa | 299,333 | 296,667 | 316,667 | 316,000 | 322,000 | 322,000 | 325,333 | 314,000 | 1.61 |

| Total | 19,492,667 | 19,368,000 | 19,425,333 | 19,324,000 | 19,572,667 | 19,657,333 | 19,580,000 | 19,488,667 | ____ |

As its proper natural conditions and the vast territory, the Brazilian sugar industry is one of the fastest growing industry in the world. There is an all year round demand for sugar, no distinct slack season and peak season. The sugar production in Brazil is nearly 20 million tons a year. Therefore, a large amount of sugar bagasse is produced for the biomass pellet market.

The Introduction of Sugarcane Bagasse Pellet

Unlike the other biomass wastes, the sugarcane bagasse is used as a fuel in the sugar mills. But with its low density, the thermal efficiency is extremely low. With the biomass pellet equipments, we can press the sugarcane bagasse into pellets, which will improve the density, durability and the combustion performance.

According to the component analysis of the sugarcane bagasse, there is 18.6% of lignin in the sugarcane bagasse. The lignin is a kind of natural glue to stick the pellet, when the temperature of the bagasse reaches 120-160 degree centigrade, the soluble part of the bagasse start to dissolve. With a temperature of 180 degree centigrade, the lignin is softening and plasticizing. At this time, the lignin of the sugarcane bagasse can glue the fibers together under a certain pressure range.

The fresh wet sugarcane bagasse normally contains a moisture about 48%-50%. For the further utilization, the moisture content of sugarcane bagasse must be dried to about 12%. Otherwise, the redundant moisture will be evaporation during the high temperature extrusion process, and the steam may cause a crack surface of the bagasse pellet.