Pellet Mill Ring Die Installation

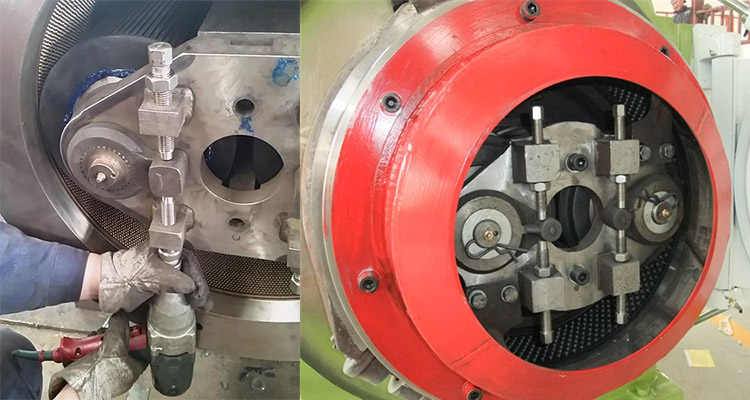

There are three pellet mill ring die installation methods, straight sided installation, conical sided installation, holt hoop installation. It is easy to install ring dies use the straight sided installation method. Straight sided installation makes the ring die steady, the ring die is not easy to tip. But the fixing bolt of the ring die is easy to break, so it is not suitable for industrial ring die pellet mill. Conical sided installation makes the ring die maintain perfect centering performance and great transmission torque. The fixing bolt of ring die installed by conical sided installation method is not easy to break, but using conical sided installation method, the installer must have some certain techniques and be very careful. Otherwise, the ring die may be tiptilted during installation. Holt hoop installation is suitable for small pellet mill ring die installation. This method need short install period. But the disadvantage is that the holt hoop installed ring die can not be turn-over, you can only use one side of the ring die.

Pellet Mill Ring Die Options

According to the features of pellet mill ring die, there are multiple factors needed to consider when we try to choose a ring die. But in actual working situation, some factors are pre-designed, such as the installation method of ring die, ring die linear velocity, and ring die working area, etc. These factors has been determined when we make the purchase. Some other factors can be controlled by choosing the professional ring die pellet mill manufacturers, such as the ring die materials, heat treatment intensity and abrasive resistance, die hole porosity and roughness, etc. Generally speaking, The pellet mill ring dies that are produced by professional ring die pellet mill manufacturers can reach the performance requirements of industrial wood pellet production. Because many of the procedures require professional equipment, such as the manufacture of the die hole and the ring die heat treatment, the quality of these manufacture process must be ensured by professional gun-drill and vacuum heat treatment equipment, common drill machine and heat treatment method can not produce high quality ring dies.

Pellet Mill Ring Die Utilization

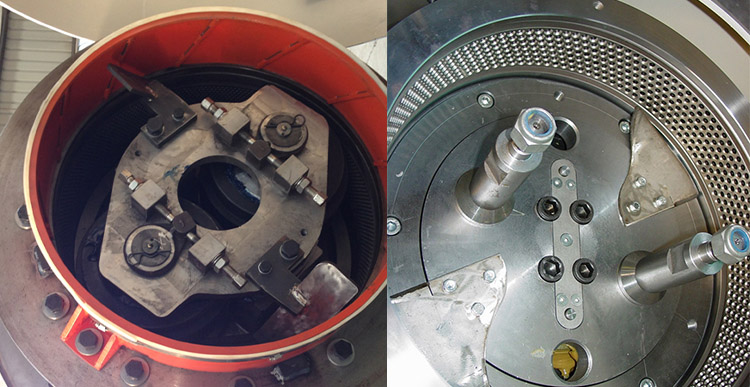

The key of using pellet mill ring die is to adjust the space between ring die and rollers properly. The proper space between pellet mill ring die and rollers is between 0.1-0.3mm. Normally, there is bigger space between new ring die and new rollers, and smaller space between used ring die and used rollers. Moreover, ring die with large die holes needs bigger working space, and ring die with small die holes needs little working space. For the operators, it requires actual operate experiences to adjust the working space between ring die and rollers masterly.

Also, there are several other matters that need to be paid attention to: firstly, before we start the pellet mill with a new ring die, the ring die must be cleaned by oil, in order to remove the burrs on die holes. Normally, new ring dies need to be cleaned no more than half an hour. If the new ring die has poor roughness, sometimes, we can mixed 20%-50% fine sand in the oil to clean the ring die. Secondly, during the pellet mill working period, we must avoid using raw materials with hard particles such as sand, stone, metal particles, small bolt, scrap iron, etc. Thirdly, for the ring dies that have been installed symmetrically, we can turn it over after a certain working period, in order to maintain the ring dies wear evenly. Fourthly, the ring die must not be tipped after the installation. Otherwise, the evenness of the ring die abrasion can not be guaranteed. And the bolt to fasten the ring die must maintain certain seating torque, in order to avoid bolt breakdown during the pellet mill working process.

Pellet Mill Ring Die Maintenance

It is a necessary step to ensure the ring die operation performance and extend the serve life of ring dies. There are several tips to maintain ring dies when using a ring die pellet mill.

Firstly, when we change a ring die, we should extrude out the residual materials with non-corrosive oil. Therefore, when we use the ring die again, it can discharge wood pellet smoothly, and also, it can prevent the die hole from corrosion. Secondly, after using the ring die for a certain time, we have to check the wear patterns of the ring die. Thirdly, if the majority of the die holes have been blocked, we can soak or cook the ring die by oil to soften the material. Fourthly, ring dies must be stocked in a dry and clean place. Wet environment may cause the corrosion of ring dies which reduce the ring die serve life.