Pellet plant, is a kind of manufacture facility which uses the pelletizing technology to mold the raw material into pellet product. Due to the raw materials and application of the pellet, there are many different kinds of pellet products in the market, such as: wood pellet, biomass pellet, animal feed pellet, iron ore pellet, and plastic pellet. It is obvious that the type of pellet plant is different based on the different kinds of pellets.

What Kind of Pellet Plant are We Talking About?

In order to dig more useful information about the pellet plant, the first thing is to clarify that the pellet plant we are talking about in this article is the biomass pellet plant ( include the wood pellet plant ).

Biomass pellet plant has a short history compare with the animal feed pellet plant. Back to 1900s, the elder generation has successfully developed the core equipment of the pellet plant — pellet mill, and soon has been widely accepted by the animal feed industry. The notice of biomass pellet plant is in the 1970s, when the first oil crisis occurs, the price of crude oil is raised from $3 per barrel to $13 per barrel. As the globe energy demand is highly depend on the crude oil, therefore, it triggers the most serious financial crisis of the capitalist countries after the second world war. And along with the expediting of urbanization and industrialization process, the environmental pollution becomes more and more serious. Therefore, the eager of finding an alternative renewable fuel to reduce the dependency of oil and improve the environment makes the biomass pellet a new concern around the world.

Biomass is the organic remains of the living organisms, such as the wood remains, crop remains, municipal solid waste, etc. It is the source to set fire since the fire has been discovered, and even now, in some developing countries, people still use biomass to make fire. But the biomass materials are irregular in shape and normally low in density, which makes the combustion efficiency extremely low and hard to transport. Thanks to the pelletizing technology, the raw biomass materials are now molded into biomass pellets with regular shape and high density. With a sufficient combustion performance and high energy density, the biomass pellet becomes a commercial product to supply both the domestic and industrial heating and power generation industry. Where are is a need, there is a supply. A large number of biomass pellet plant has established whole world round.

What Equipment do We Have in the Pellet Plant?

There is no doubt that the pellet mill is the core equipment of the biomass pellet plant, despite of that, a classic biomass pellet plant normally consists of eight steps: initial size reduction, drying, initial sieving, grinding, pelletizing, cooling, final sieving and storage. Each step has its typical equipment.

Wood chipper

Wood chipper, aka wood crusher, is the typical equipment of the initial size reduction process in a biomass pellet plant. As the raw biomass materials are normally irregular in shape, so if we cut the initial size reduction process, it will significantly increase the energy consumption of the following steps and even shorten the service life of the other equipments. Take the drying process as an example, the bigger particles require longer drying period, and the smaller particles require shorter drying period. So if we put the irregular shaped biomass materials into the dryer, then the small particles may be over dried while the bigger particles are still moist. Hence, the wood chipper is one of the most important and costly equipments in biomass pellet plants.

Rotary drum dryer

The rotary drum dryer is the common equipment of the drying process in a biomass pellet plant. The best quality biomass pellet maintains a moisture content about 8% – 12%, but the raw biomass materials are easily to be affected by the surroundings. The moisture content of the raw materials is a strong influencer of both the production performance and the product performance. Take the biomass pellet product as an example, a best quality biomass pellet remains a longer combustion period with little visible smoke. But how could we control the combustion smoke? By controlling the moisture content of the raw materials. The lower moisture the raw materials are, the less smoke the biomass pellet will produce. Nevertheless, we still need some water content to perform as the binder or lubricant of the pellet, so ,the ideal moisture content of biomass materials is about 8%- 12%.

Magnetic separator

A magnetic separator is used in the initial sieving process in a biomass pellet plant. After the process of the wood chipper, the biomass materials remain a small size, so the contaminants ( such as metal particles, stones ) are the unavoidable problem. The magnetic separator is not a necessary equipment of the biomass pellet plant, but if the source of the biomass materials are easily contaminated by the metal particles, the magnetic separator is recommended.

Hammer mill

A hammer mill is the most effective machine for the grinding process in a biomass pellet plant. It is also used for size reduction. The difference between hammer mill and wood chipper is the diameter of the raw materials. A wood chipper can process the raw materials with a diameter under 2000mm, and the raw materials after the process is about 50mm in diameter. A hammer mill is used to reduce the size of the raw materials from a diameter about 50mm to a diameter under 5mm. In order to enhance the pellet mill serve life and cut the energy consumption of the biomass pellet plant, use a hammer mill to grind the raw materials before pelletizing is a necessary step.

Pellet mill

Here comes the core part of a biomass pellet plant. A pellet mill is used to pelletize the grinded raw materials into regular pellets. The choice of pellet mill may be different due to the different scale of the pellet plant customers. However, there are two types of pellet mill in consideration, the ring die pellet mill and the flat die pellet mill, which can be distinguished by the different scale pellet manufacturing requirements. The ring die pellet mill for large scale pellet production, and the flat die pellet mill for small scale pellet production.

Counter flow cooler

A good quality biomass pellet always remain with a proper rigidity. But during the pelletizing period, the friction of the rollers and the die produced a extremely high temperature, therefore, the biomass pellets discharged by the pellet mill is hot and fragile. In order to regain the rigidity, a cooler is needed. The types of coolers are various, Gemco mainly adopted the counter flow cooler, which is the most advanced cooler for biomass pellet plants.

Pellet screener

The fine particles is also an unavoidable problem during the biomass pellet manufacture process. The pellet screener is a necessary step after the cooling step in a biomass pellet plant. A good quality biomass pellet always remains less fine particle. Right before the package step, a final sieving step is necessary which aimed at removing the fine particle from the well formed biomass pellets.

Automatic bagging machine

An automatic bagging machine is the standard equipment for package process in a biomass pellet plant. Due to the different customer types, there are two types of bagging machine in consideration, the retail bagging system and the bulk bagging system. The biomass pellet plant customers can choose the bagging machine type based on their customers’ requirements.

How is the Biomass Pellet Market?

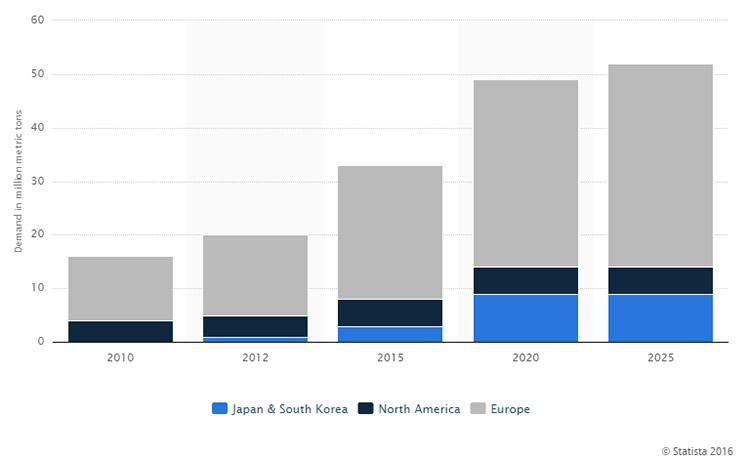

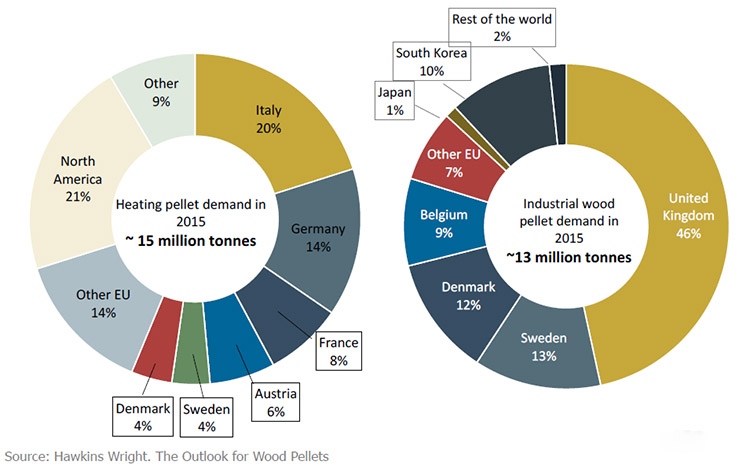

The biomass wood pellet is used as an alternative to fossil fuel. The global demand for biomass wood pellet has been remarkably developed during the last decade. The utilization of biomass wood pellets can be divided into two parts: the residential purpose and the industrial purpose. The residential purpose is for individuals to buy wood pellet for their family heating system. During the heating season, many people in Europe and North America use the pellet stove to generate heat in their house. As a well accepted heating fuel of the pellet stove in Europe and North America, you can purchase wood pellet online or in the supermarkets. The industrial purpose is for the industrial plants to buy wood pellet for heat and power generation. To meet the requirement of the 2020 climate and energy plan presented by the European Commission, the power station and the central heating system of Europe uses wood pellet as a co-firing fuel to generate heat and power. The global wood pellet demand in 2015 is placed below:

From the global wood pellet demand chart you can easily find out that European countries are the main wood pellet market and excepted to stay the position of the most important target market for wood pellet till 2025.

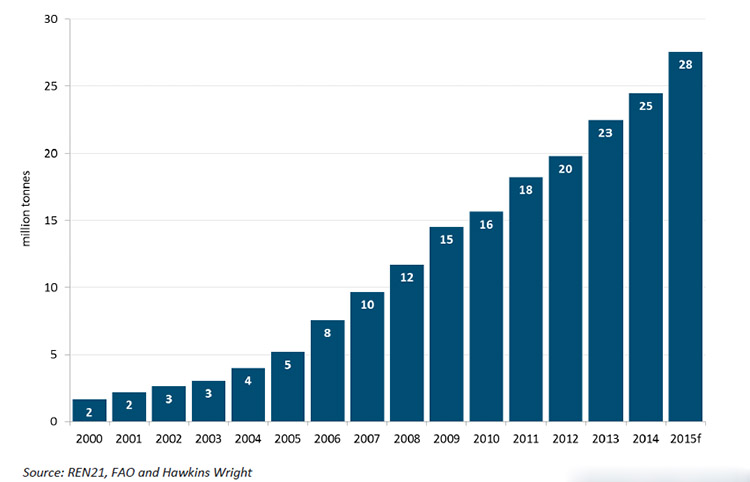

As we have known the demand volume of wood pellet, some people may still have some questions about the supply chain. Is the wood pellet manufacturing industry an intensely competitive market? Is it hard to develop a wood pellet demand market for the pellet plants? To answer these questions, we have to see the wood pellet production chart in 2015:

The global wood pellet manufacturing industry is a healthily developing market. The wood pellet production volume and demand volume in 2015 keeps balance. Based on the wood pellet demand in the past decades and the international environment, the experts have shown that during the following decade, though the European countries will still hold their dominant position, but East Asia will become a new growth factor of wood pellet consumption. However, the global demand for wood pellet will expect to be doubled during the next decade.

global wood pellet demand 2010-2025