With the rapidly development of biomass energy industry, wood pellet becomes one of the most important substitute of fossil fuels. As the demand of wood pellet grows, large quantity wood pellet production has becoming an urgent problem for global renewable energy strategy. Therefore, wood pellet industry adopts the technology of feed pellet making machine, and developed both large and small pellet making machine for wood pellet production.

How Many Types of Pellet Making Machine?

Talking about pellet making machine types, there are many different ways to classify pellet making machines.

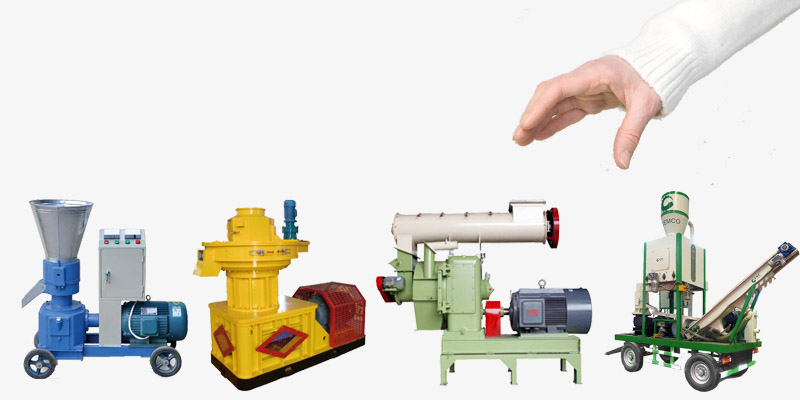

Pellet making technology is not specially designed for biomass pellet manufacture. It has been widely applied in many different industries, such as animal feed industry, biomass energy industry, paper making industry, etc. Based on the different end products, there are animal feed pellet making machine, wood pellet making machine, biomass pellet making machine, paper pellet making machine, plastic pellet making machine, iron ore pellet making machine, etc. For wood pellet making machines, there are also flat die pellet making machine, and ring die pellet making machine. Moreover, ring die pellet making machine can also be divided into horizontal pellet making machines and vertical pellet making machines. And flat die pellet making machine can be divided as rotary die type pellet making machines(D-type pellet mill) and rotary roller type pellet making machines(R-type pellet mill).

Some people may feel a little bit confused about wood pellet making machines. There are too many wood pellet making machine types, if I want to make some wood pellet for my own house or start a wood pellet plant, which type of wood pellet making machine should I choose? In fact, there are distinguishing differences between different types of pellet making machines. For example, flat die pellet mill also known as small pellet making machine, as it is mainly used for small scale wood pellet production. For the farmers who wish to make their own animal feed, or wood pellet fuel for their own home heating system, small pellet making machine will definitely help. On the contrary, ring die pellet mill is known as large pellet making machine with a capacity over 1ton per hour. So it is mostly used in medium and large scale wood pellet production, such as school heating systems, central heating systems, wood pellet plants, etc.

Although, the pellet production technology are similar, the detail pellet making machine specifications are different based on the various raw material hardness. Just tell your pellet making machine manufacturer the raw material you plan to use and the pellet quantity you plan to make, the professional pellet making machine manufacturers will recommend the suitable pellet making machine for you.

How to Operate A Wood Pellet Making Machine?

In order to maintain the stable working performance of pellet making machines, there are a strict pellet machine working procedure you have to obey:

- Turn on the power of the air blower and conveyor.

- Turn on the main engine conveyor.

- Turn on the motor of raw material silo, and shut off the power of air blower.

- Turn on the power of pellet machine main engine.

- Turn on the power of pellet machine feeder.

- Start to feed pellet raw materials (the feeding frequency must be slower than normal feeding speed.)

- Pay attention to the raw material quantity in the silo.

- Pay attention to the wood pellet output, see if the pellet machine is operate as usual. If there is anything unusual of the pellet product, just adjust the pellet machine settings immediately.

How to Maintain a Wood Pellet Making Machine?

The proper maintenance of a pellet making machine will definitely enhance its serve life. Both the pellet machine die and rollers are wear parts, if there is no proper maintenance or use wrong maintenance procedures, the wear parts can be quickly wore, and only the spare parts fee can cost you a fortune. In the following parts, we will talk about some standard pellet machine maintenance procedures.

- Before you start the pellet machine, you should check all the screws, see if there is anyone loosening up.

- Before you start the pellet machine, check the distance between pellet machine rollers and die, normally the clearance is about 0.1mm – 0.3mm, you can adjust the clearance through the housing pin of the rollers.

- Before using the pellet machine for the first time, you should use oil materials to grind the pellet machine rollers and die for at least one hour. Moreover, when you stop pelletizing process each day, you can use the oiled material to run the pellet machine for a while, therefore, the residual wood materials will be press out of the pellet machine die holes.

- When the pellet machine runs for about six months, the pellet making machine should have an overall maintenance and add lubricant to the pellet machine regularly.

Despite of the above maintenance method, there are more complicated maintenance methods for large pellet making machines. For wood pellet plants, the maintenance of pellet machine is more complicate, as the productivity are different and pellet plant has more complex pellet equipment combinations. In that way, find a professional pellet plant supplier is very important. They will help you set your complete plant layout, pellet equipment purchase, complete pellet line construction, etc.