In the wood pellet plant faq part 1, I have included several questions regarding to wood pellet plant set up, let continue with more questions.

Q 06: Is there any differences between the biomass pellet mill and the feed pellet mill?

A 06: For a pellet plant investor, to choose the right pellet mill for the pellet plant is very important. And there may be some feed pellet plant owners hope to explore a biomass pellet business with their feed pellet mills. The working principles of the biomass pellet mill and the feed pellet mill are the same. But the characteristics of the feed pellet and biomass pellet are different, especially the moisture contents of the feed pellet and the biomass pellet. Therefore, the feed pellet mill can not be used directly to produced biomass pellet. However, if you looked for the history of pellet mill, you can find out that the pellet production technology is first utilized in feed production industry, and the manufacture technology of the first biomass pellet mill is adopted from the feed pellet mill, but with a different technological parameters and device layout.

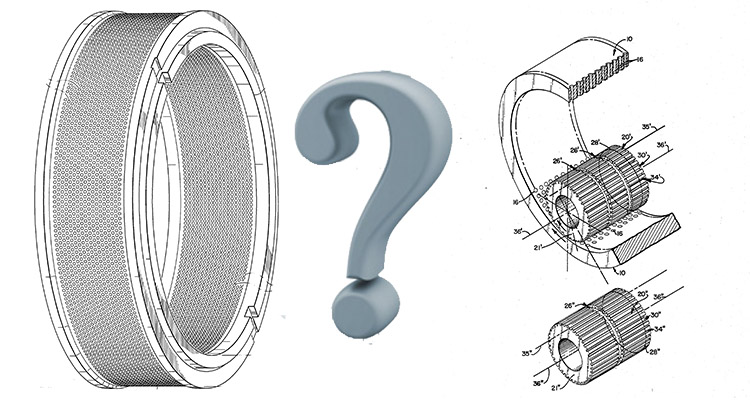

Q 07: The weariness of the screw pellet mill is a serious problem, there are many screw pellet plant stopped production due to the high cost of spare parts. How about the wear cost of the ring die pellet mill?

A 07: Yes, the screw pellet mill does have a high consumption of its wearing parts. About this confusion, we have done a test to measure the consumption cost of wearing parts of the screw pellet mill and ring die pellet mill.

The consumption cost of wearing parts of the screw pellet mill

| Capacity | 100 kg/h |

| Screw rod working life | 80 h |

| Screw rod cost | $ 61.64 |

| Consumption cost of wearing parts | $ 7.7 /t |

The consumption cost of wearing parts of ring die pellet mill

| Capacity | 300 kg/h |

| Ring die working life | 2000 h |

| Ring die cost | $ 616.4 |

| Roller working life | 500 h |

| Roller cost | $ 61.64 |

| Consumption cost of wearing parts | $ 1.44 /t |

| Capacity | 2 t/h |

| Working life of ring die and roller | 5000 t |

| Cost of ring die and roller | $ 1848 |

| Consumption cost of wearing parts | $ 0.37 /t |

From the charts above, you can easily find out that although the cost of the ring die pellet mill is higher than the screw pellet mill, but consumption cost of the wearing parts of ring die pellet mill is much lower than the consumption cost of the wearing parts of screw pellet mill. So, for the long term benefits, ring die pellet mill is the commercial choice for the biomass pellet plant investors.

Q 08: How is the prospects of the biomass pellet fuel market?

A 08: The biomass pellet fuel is a kind of the renewable energy, it is a developing market in Europe and North America with great exploitation potential. If the cost of material in the area is affordable ( such as the timber wastes and the corn stalk with a diameter under 50mm), and the electric power supply is adequate, you can start your biomass pellet manufacture business. Moreover, you don’t have to only be a biomass pellet manufacturer, but also be a pellet stove manufacturer or wholesaler.

Q 09: How much is the cost of production of the wood pellet for a 2 – 3 t/h wood pellet plant?

A 09: The cost of production can be different in different areas around the world, but the calculation method of cost of production for wood pellet plant stays the same. The cost of production for a wood pellet plant consists of the labor cost, the management fee, the cost of materials, the electric charge, the energy consumption during drying process, the depreciation of equipment, the consumption cost of wearing parts, and the maintenance fee. You can calculate your cost of production for your pellet plant based on the price standard in your location.

Q 10: It seems like the biomass pellet industry has been praised highly, can you tell me about the prospects of the biomass pellet market?

A 10: Every industry has its own unique entry point for the market, this is nearly the most important thing when you enter into a new market. If you missed the entry point of the industry, it will cost you a lot of time and effort, after the market has been fully developed, it may be extremely difficult for you to have a share in the industry.

Right now, the renewable energy still stays in such a small scale business, and has not been fully known by the majority of the society. Among all kinds of renewable energy, only the biomass pellet has the potential to be a fuel with the large scale application. Moreover, the biomass pellet is most likely the best substitute fuel to replace the fossil fuel.

Among all kinds of biomass, the woody pellet is the only one that can fully reserve the energy in it and be fully combusted and release the thermal energy in it. Otherwise, the other biomass material will definitely lost part of the energy. Therefore, wood pellet is the most commercial product among all kinds of biomass pellet.

If we looked back, it is easy to find out that coal is the cheapest and most popular fuel in the world, but it is also a main polluter to the environment. As the environmental protection awareness of people enhanced, some people start to focus on the substitute for coal. As the world economy has been depended on coal for such a long time, especially for the developing country, it is not possible for them to abandon the coal fuel. But we has to know that the renewable energy is the trend during the following two decades, and it is already widely spread in Europe and North America. Wood pellet is the perfect win-win solution that can keeps the cost of energy low and be environment friendly at the same time.