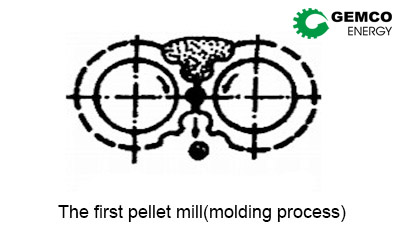

The First Pellet Mill in the World

When we talked about the pellet mill, or pellet press, the common misunderstanding is that it is a extrusion machine but not a molding machine. In fact, the first pellet mill starts to work on the molding process in 1900. The pellet mill is consist of a pair of rollers which has the same form. The rollers are covered with hemispherical grooves and rotate in the opposite directions. This type of pellet mill has a high sensitivity of the installation of the two rollers, the hemispherical grooves on the two rollers must be matched exactly, so that the raw materials can be molded into spherical pellets. If the hemispherical grooves do not match, the molded pellets are flawed. Generally, the pellets that made by the first pellet mill maintain a low density and low strength, and during the pellet manufacturing process, it doesn’t produce the chemical changes in raw materials. The technology of making the first pellet mill is not mature, so the first mill has a small capacity but a high energy consumption. Therefore, it is failed to be a commodity due to that it is not widely accepted by the pellet plants. However, you can still find out the similar equipment in some other industries.

The Development of Pellet Mill

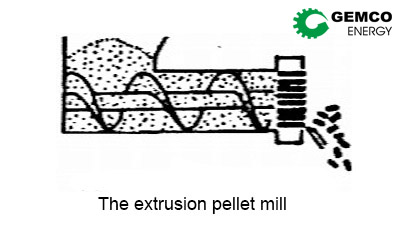

The development of first extrusion pellet mill

In 1910, the first extrusion pellet mill which is developed by the Sizer company in UK is available in the market. As it is soon popular in the feed pellet plants, it is the first type of pellet mill which become an actual commodity in the pellet manufacturing industry. Compare with the modern extrusion pellet mill, the pellet mill in 1910 adopts the same working principle. The raw materials are fed in a helicoid conveyer to move forward by the compelling force, and finally being extruded out of the molding holes with a columnar form and then cut by a knife.

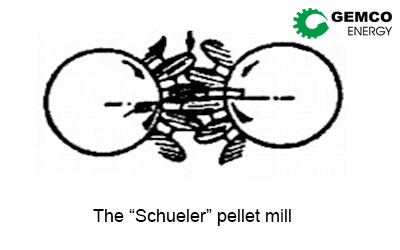

The development of “Schueler” type pellet mill

In 1920, the “Schueler” type pellet mill is produced based on the compression process conception which is proposed by Schuyler. The “Schueler” pellet mill is made by two rollers which looks like gears, the rollers will extrude the raw materials, and then discharged from the holes on the teeth of the rollers. But the “Schueler” pellet mill is easy to wear, so the cost of using the “Schueler” pellet mill is higher than the other types of pellet mill.

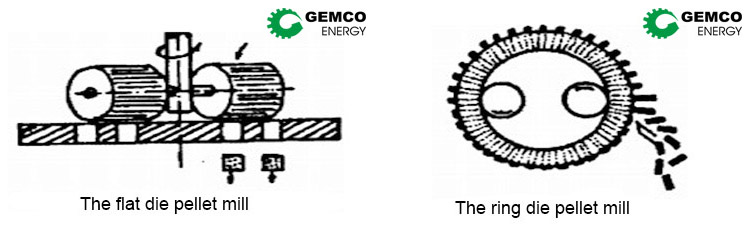

The development of flat die pellet mill and ring die pellet mill

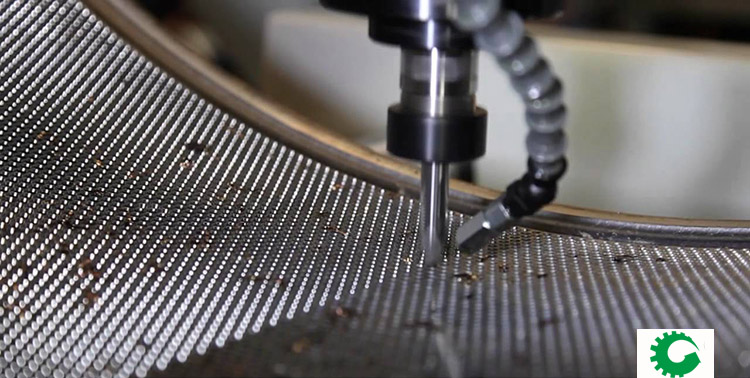

Beyond that, the first flat die pellet mill is manufactured also in 1920. The successfully development of flat die pellet mill has significantly improved the productivity and the mechanical wear performance of the pellet mill for the pellet plant. After quite a short time of using the flat die pellet mill, the owner of the pellet plant realized that the liner velocity of the contact point of the flat die and the rollers is different along the radial, which will impact the quality of the pellet products and the equal wear of the roller and the die. Due to the situation, some people looked to the development of ring die pellet mill, and the first ring die pellet mill had been successfully developed at the same time. The ring die pellet mill is consist of a ring die with multiple holes on it and several rollers. Initially, the ring die pellet mill operate with a rotary roller model, through years of persisting efforts, the ring die pellet mill is now adopted a rotary die model. Along with the rotated ring die, the raw materials are extruded in the holes and molded as cylinder, then cut in a certain length by the knife just outside the ring die.

Modern Manufacture Technology of Pellet Mill

The study of pellet mill starts early in foreign countries. In 1931, the first vertical ring die pellet mill is developed successfully by CPM company in USA. Soon after that, the first horizontal ring die pellet mill is also developed by the same company in 1934. At the same time, UMT company in UK also manufactured their own pellet mill for the pellet plants. After 1970s, the oil crisis occurs, which makes wood pellet become a popular substitute of fossil fuel and a lot of wood pellet plant has been established ever after. Therefore, some European countries start to develop and produce their own ring die pellet mill.

China has a short history of developing pellet mills. The first pellet mill in China is based on the ring die pellet mill of UMT company, and is produced in 1970s. Meanwhile, there are many universities and research institute start to develop the manufacture technology of pellet mills.

After the ring die pellet mills are put on the market, the working principle of the pellet mill is mature, only the manufacturing level and technical performance have been improved over and over again.

Continue your reading with other pellet plant handbook post:

Pellet Plant Handbook : ENplus Certification for Wood Pellet Plant

Pellet Plant Handbook : Wood Pellet Standards in Europe

Pellet Plant Handbook : The Physical Characteristics of Wood Pellet

Pellet Plant Handbook : The Chemical Characteristics of Biomass Pellet

Pellet Plant Handbook : The Interdependencies Between Biomass Pellet Parameters