For the production of wood pellet plants, the physical characteristics of the pellets greatly effects the wood pellet quality. Therefore, in order to control the quality of the wood pellets, the first thing to do is to determine the applicability of biological raw materials, and the evaluation criteria for the raw materials.

For this purpose, the EN 14961-2 is a useful reference for the wood pellet plants, as it has already posed a limit on some constituents of wood pellets. According to the standard, the raw materials for wood pellets must be untreated biomass products from primary agriculture and forestry.

The parameters of the wood pellet raw materials are determined by the pelletization technique and the combustion technique. The international wood pellet programme, EU – ALTENER project “ An integrated European market for densified biomass fuels ” has analyzed the wood pellets from different wood pellet manufacturers in six European countries, i.e. Austria, Sweden, Spain, Italy, Norway, and the Czech Republic. The main goal of this project is to compare and measure the particular parameters of wood pellets, which can provide an overview of the quality of the wood pellets in Europe.

The Size Distribution of Pellet Raw Materials

The size of the pellet raw materials is determined by the diameter of the pellets, and the pellet mill technology. For sawdust, the maximum size of sawdust to produce wood pellet is 4mm. So it is necessary to set up the hammer mill which is the grinding equipment for a pellet production line. However, no matter what raw materials you choose, it should be as homogenous as possible.

The Dimensions of Wood Pellets

The dimensions of wood pellets determine the choice of the feeders and the furnace technologies of the pellet stoves. The dimensions of wood pellets is one of the main influencers of the conveying and combustion behavior of the pellet fuel. The bigger the fuel particle is, the feeding appliances have to be more robust, and the longer combustion time it need. In that case, the diameter and length of the wood pellet has to be standardized. The diameter of the wood pellet is determined by the diameter of the die holes of the ring die pellet mill. During the pelletizing process, the raw materials in the pellet mill are pressed to pass the holes on the pellet die, so the diameter of the pellets is determined by the diameter of the pellet die. The length of wood pellets is controlled by the knife outside the pellet holes. The original pellet mill does not have the knife, the length of the wood pellets is just left to pure chance of the stiffness of wood pellets, which makes the pellets are too long to block the feeding system of the pellet stoves. In order to ease the system outage of the pellet furnaces, the length of wood pellets is determined to be no more than 40mm.

The Bulk Density of Wood Pellets

The bulk density of wood pellets is a main effecter of the wood pellet economic performance. The higher bulk density the wood pellets are, the higher energy density the wood pellets may have, and the less costs the transport and storage may need. Hence, a higher bulk density is a certain way for the wood pellet producers, retailers to improve the economic performance of their pellet plants. According to the European standard EN 14961-2, the minimum bulk density of wood pellets is 600 kg/m³, normally a bulk density of 650 kg/m³ is assumed in the high quality wood pellets.

The Particle Density of Wood Pellets

The particle density of wood pellets influences the combustion performance of the wood pellets. The higher the particle density the wood pellet has, the longer combustion time the wood pellet remains. Also, the bulk density is influenced by the particle density of the wood pellet. The measurement method of wood pellet particle density is described by the European standard EN 15150, and the particle density of wood pellets indicated a range between 1.12 and 1.30 kg/d m³.

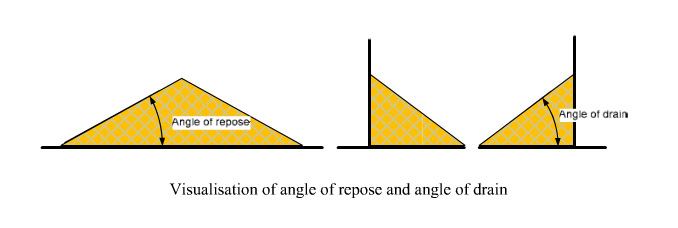

The Angle of Repose And Drain for Wood Pellets

The angle of repose and the angle of drain are used in bulk wood pellets storage, especially when designing the storage facilities for wood pellets. The angle of repose is an angle when we pour the wood pellets from the top and generate the standing cone or flat ramp on the horizontal surface. For large scale pellet trade, the angle of repose is 28-32 degrees. The angle of drain is an angle created when the wood pellets draining through an orifice on the flat, it is normally steeper than the angle of repose. The angle of drain is approximately 33 to 37 degrees.

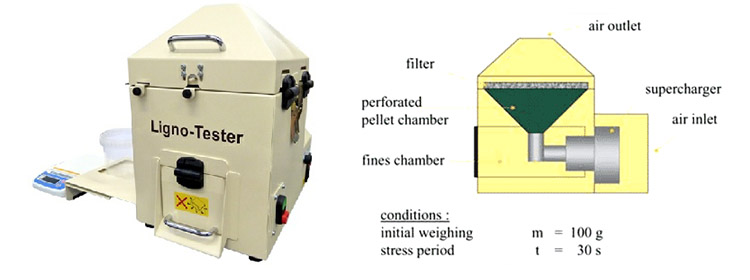

The Mechanical Durability of Wood Pellets

The mechanical durability of the wood pellets is one of the most important parameters which is defined by EN 15210-1 as the ability of densified biofuel units to remain intact during loading, unloading, feeding and transport. The ligno-tester is one of the mechanical durability testers which has been widely used in recent years. According to EN 14961-2, the mechanical durability of wood pellet is no more than 97.5 wt.% for A1 and A2 pellets. The fine particles can bridge in the storage facility of the users and block the feeding screw of the pellet stove. Furthermore, the large amount of fine particles is a potential danger for everyone as it is may cause explosion during storage and production. Therefore, to produce the wood pellets with high mechanical durability is the main goal for every pellet plant.

Continue your reading with other pellet plant handbook post:

Pellet Plant Handbook : The History of Pellet Mill

Pellet Plant Handbook : ENplus Certification for Wood Pellet Plant

Pellet Plant Handbook : Wood Pellet Standards in Europe

Pellet Plant Handbook : The Chemical Characteristics of Biomass Pellet

Pellet Plant Handbook : The Interdependencies Between Biomass Pellet Parameters