Why Use Biomass Pellets for Industrial Production

Biomass pellet fuel is a new types of compression molding solid fuel which turns the agricultural wastes and forestry wastes such as corn stalk, wheat straw, wood shavings and wood chips into useful products. To burn the biomass pellets, we must use the biomass pellet boiler which is a little bit different from coal boiler.

Coal boiler has been the main boiler for industrial production for quite a long time. As we all know, coal is a heavily polluted fossil fuel, and there are even some unscrupulous manufacturers that used bad quality coal with high sulphur content. The black smoke from burning coal and sulphur pollution will impact the atmosphere directly. Recent years, the environment pollution problem becomes more and more serious, many people realize burning coal is one of the main pollution sources. Therefore, more and more people require the industrial manufacturers to use non-polluted energies such as natural gas and electricity instead of coal. But we have to know that the prices of natural gas and electricity are much higher than coal. If we use natural gas and electricity for industrial production, the prices of products we need will raise heavily. So it is not doable for the industrial manufacturers use natural gas and electricity for energy generation.

Unlike natural gas and electricity, biomass pellet is also a non-polluted renewable fuel but with an equal price with coal. In order to protect our environment and maintain the average product price, biomass pellet become the preferred fuel choice for industrial manufacturers. Therefore, thousands of biomass pellet plants has been establish in recent years, and a wide range of biomass pellet combustion equipment have been developed since then, such as pellet grill, pellet stove, industrial pellet boiler and so on. The structure of normal coal boiler does not suitable for biomass pellet combustion. In order to maximize the biomass pellet combustion performance, the traditional boilers must be transformed so that the biomass pellet can be fully burned and solve the pollution problem.

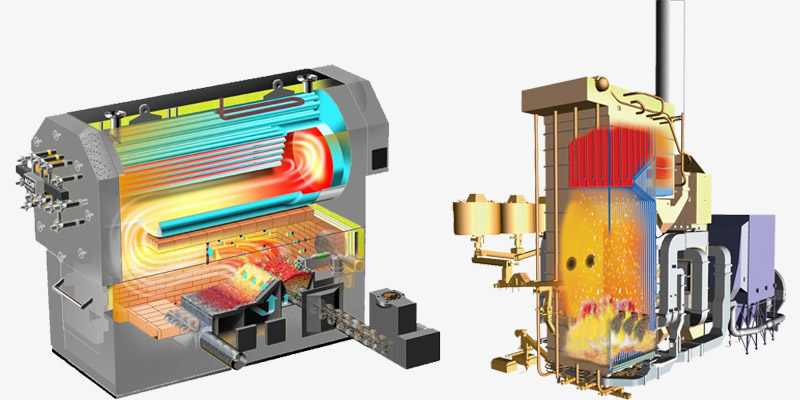

Biomass Pellet Boiler Working Principle

The biomass pellets will be spread on the upper fire grate evenly through the feeding port. When the fire started, the induced draft fan also starts, so the volatile contents of the biomass pellets are extracted out. The fire keep burning down, there is the high temperature area between the refractory belt and the suspended fire grate which create environment for stable continuously burning performance. Both the fully burned pellet ashes and the un-fully burned pellets that are smaller than the upper fire grate gap will drop down to the high temperature suspended fire grate and then keeps burning and dropping on the lower fire grate. At last, the fully burned pellet ashes will pass through the lower fire grate, and drop in the ash discharge port. When the ashes pile up to a certain quantity, clean the ash discharge port.

During the falling process of biomass pellets, the secondary air distribution outlet can supplement some oxygen so that the biomass pellet can keep on burning on the suspended fire grate. Also the third air distribution outlet will supplement oxygen for the biomass pellets burning on the lower fire grate.

Biomass Pellets Boiler Combustion Features

The high temperature area of the biomass pellet boilers can be rapidly formed, so that the fire grate pellet combustion, combustion in gas phase and suspension combustion are operating stably. The flue gas stays in the high temperature combustion chamber for quite a long time, and after several times oxygen replenishment, the biomass pellets are fully burned, therefore, biomass pellets maintain high using rate, which solved the black smoke pollution problem perfectly.

If you use the professional biomass pellet boiler, the smoke emission concentration is low, which means the chimney is not a necessary equipment.

Biomass pellets shows a stable continuous burning performance, which ensure the continuous energy requirements of industrial production.

Biomass pellet boilers are highly automatic, therefore the labor intensity is low. Biomass pellet boilers are easy to operate, there is no need for the complicated operation procedures.

Biomass pellets has a wide application range, not only for industrial production energy generation, biomass pellets can also used for residential house heating, cooking , BBQ, and so on.

Biomass pellet boilers adopts the gas-solid phase split phase combustion technology. Therefore, the volatile contents that has been transport from high temperature burning chamber to vapor phase burning chamber are basically hydrocarbon. Hydrocarbon is suitable to combustion with less oxygen support, also, it can be burned without black smoke. Moreover, during the high temperature fragmentation process, the burning chamber remains hypoxic, which can effectively stop making the nitrogen contents in the biomass pellets into toxic oxynitride.