The Introduction of Small Pellet Plant Customers

Nowadays, the pellet production is widely used in various industries and markets. At first, the pellet manufacturing technology is used in the feed manufacturing industry, many farmers hold their own pellet equipment to manufacture the feed pellets by the crops from their own farm. Therefore, the small scale pellet plant is becoming popular in the feed pellet industry. After the oil crisis and the environment problems occur, the demand of using a low carbon renewable energy becomes a urgent problem around the world, which makes the wood pellet and biomass pellet growing fast in the renewable energy market. Wood pellet is recognized as a substitute fuel for both heating purpose and power generation purpose. Despite of the industrial pellet plants, there are also some small scale wood pellet plant customers. For example, the farmers may pelletize the agricultural waste into pellets for their own heating purpose or sell them to make some extra money.

Why do We Develop the Mobile Pellet Plant?

The reasons of developing the mobile pellet plant is aimed at lowering the production input and increasing the income of the small pellet manufacturers. During the contact with our customers, there are several limits of the small scale pellet manufacturers, such as the limited budgets, the limited factory site, the quality control problem and the labor costs. To solve all the above problems, a fresh idea of making mobile pellet plant is proposed by the engineers of Gemco Development & Research Department, and soon becoming widely accepted by the small wood pellet plant customers.

The Introduction of Gemco Mobile Pellet Plant

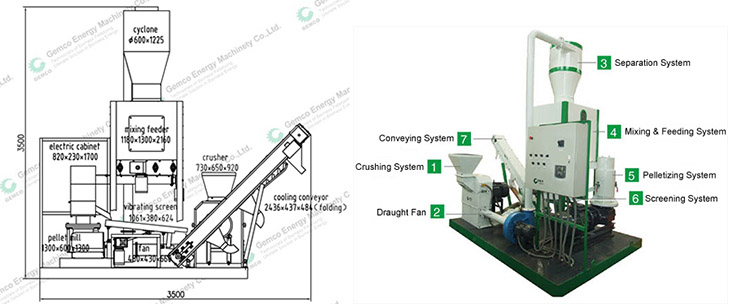

The main components of Gemco mobile pellet plant

The development of mobile pellet plant has been through three generations. Right now, the Gemco mobile pellet plant is an all in one pellet equipment for small scale pellet manufacturers, and a 100% automatic pellet machine which can help you minimize your labor cost. It is customized for the small scale pellet plant with a capacity about 250 kg – 450 kg per hour. All you need to do is feed your raw materials ( such as saw dust ) in, and then collect the well molded pellet. The main components of Gemco mobile pellet plant is listed as follow:

Hammer mill ( FSCP450D, 15kw )

This is the size reduction process of the mobile pellet plant. The recommended raw materials should maintain a diameter which is less than 20mm, and after the process, the diameter of the raw materials is about 3-5mm.

Adjustable raw material storage bin ( 0.75kw )

After the size reduction process, Gemco mobile pellet plant adopts a frequency converter, which can make the feeding capacity adjustable.

Pellet machine ( ZLSP300B R-type, 22kw / ZLSP400B R-Type, 30kw )

This is the core part of Gemco mobile pellet plant. The raw material storage bin will feed the prepared raw materials in the pellet mill automatically, then the R-type pellet mill can process the raw materials into pellet efficiently.

Vibrating sieve ( SFZD300D, 0.37kw )

The vibrating sieve of Gemco mobile pellet plant is not only a sieving equipment, but also a cooling equipment, and the particles that the sieve collected can be used to product pellet again.

Scraper conveyor ( CSGB145D, 0.75kw )

The scraper conveyor can also help to cool the pellet down and be adjustable for the actual specification of the pellet you made.

The highlight of Gemco mobile pellet plant

Small footprint

The total size of Gemco mobile pellet plant is about 3.5*2*3.5 m3, and all the equipments of the mobile pellet plant share the same base, so it is also movable.

Fully automation

The mobile pellet plant is an all in one equipment for small scale pellet manufacturers. Its automation level can shorten the production period and the labor cost.

Wide application

The mobile pellet plant is widely applied in the small scale pellet manufacturing industry. It can produced wood pellet, biomass pellet, and animal feed pellet.

High quality pellet

To ensure the quality of the pellet, every components of the mobile pellet plant adopt the latest pellet manufacturing technology and the top materials.

High safety assurance

Though it is an automatic pellet plant, the safety problem is still the top priority. Gemco uses the dust proof technology for the mobile pellet plant and installs a protecting fence on the hammer mill of the mobile pellet plant.