To set up a wood pellet plant is never simple as purchasing some pellet equipment, it is a sophisticated process that includes several stages and kinds of researches and designs. Therefore, with long time working experience in the pellet manufacture industry, many pellet plant engineering companies extend a kind of serve which is called “ pellet plant consultant”.

The name pellet plant consultant may generate the confusions such as: what can I consult for? What can the consultant benefit me? To solve the confusions, the first thing we have to do is to figure out what the professional wood pellet plant consultant is and the components the pellet plant consultant includes.

The Professional Wood Pellet Plant Consultant

To make it simple, the professional wood pellet plant consultant is the entire process between you want to build a pellet plant and the pellet plant start to work. The whole process of the professional wood pellet plant consultant includes:

The wood pellet plant feasibility study

The feasibility study of wood pellet plant is the first thing you have to do when you try to start a wood pellet manufacture business. A wood pellet plant feasibility study consists of the most valuable information the pellet plant investors may need. Normally, the feasibility study includes the pellet fuel market overview, the available feedstocks, economic viability, the policy support and the potential mill sites. All these information can help you get a clear idea about your pellet plant and the market you supply.

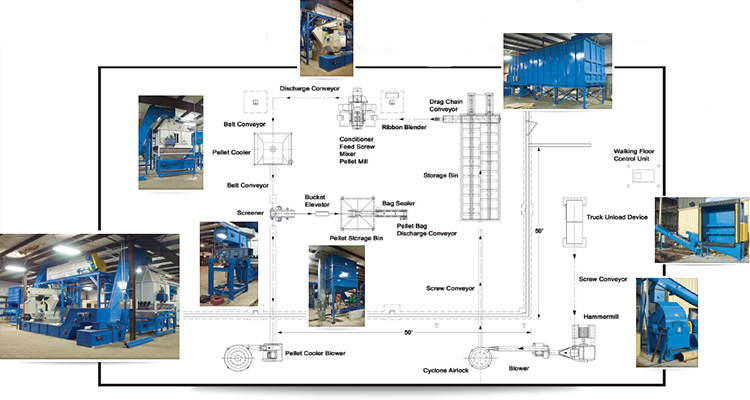

Wood pellet plant design

The wood pellet plant design is one of the most important services in the wood pellet plant consultant. In this step, the consultant company will give the pellet plant investors several specific design schemes based on the capital fund, the capacity, the raw materials, and so on. Never underestimate the importance of wood pellet plant design. The high efficient pellet plant design is based on your own situation and consists of the most suitable wood pellet equipments combination, which makes every penny of your capital fund well spent. On the contrary, the low efficient wood pellet plant design may cause many issues, such as high energy consumption, low utilizing ratio of wood pellet machines, etc. At best, these bad influencer will enhance your payback period, at worst, they may cause the mechanical fault and the financial failure of the wood pellet plant.

Wood pellet plant engineering

The wood pellet plant engineering is a part of the pellet plant consultant service that gives you the personal pellet plant solutions. During the stage, the most appeal part is that the engineers will help realize your personal desire about the machines in your pellet plant, maybe it is a specific capacity, maybe it is a customized circuit, maybe it is a machine with several functions.

Procure wood pellet equipments

After the wood pellet plant design and engineering, the wood pellet manufacturing equipment has been confirmed. In consideration of minimize the investors capital input and long term maintenance costs, a professional wood pellet plant consultant will provide you the exact wood pellet manufacturing equipment you need with a competitive price competing with the other wood pellet equipment providers.

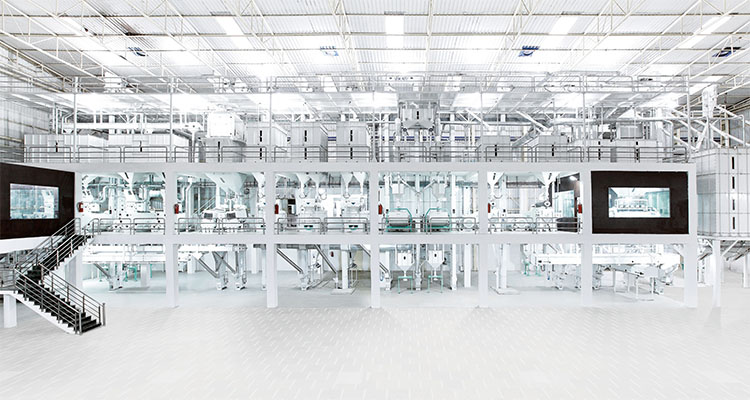

Pellet plant construction management

The engineers of the wood pellet plant consulting providers will offer an on-site supervision during the whole construction period of the wood pellet plant. It can help you find the best way to manage the construction of the facility, especially to balance the capital input, construction schedule and risks.

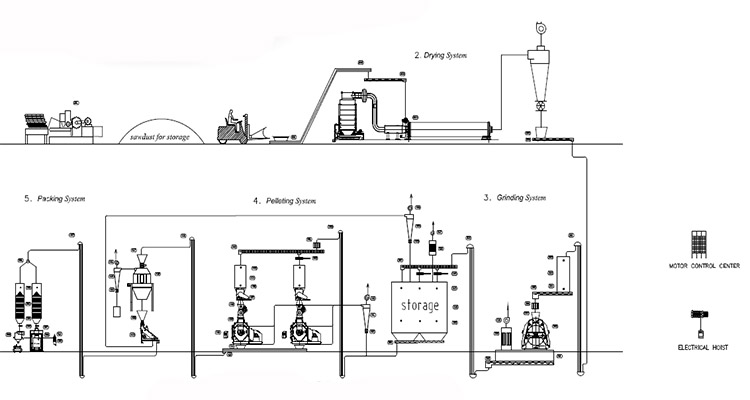

Debug the wood pellet line

When the wood pellet plant mechanical completion is achieved, the wood pellet line must go through the functional testing so the pellet plant can start up. The debugging include two parts, the individual working test and the complete working test. The individual test is used to verify the operation of the machine separately, and the complete working test is to confirm the function of the whole wood pellet line. The debugging service provides an intuitionistic validation of the wood pellet plant operation, which can help you start to run your pellet plant successfully.

Process optimization

When the wood pellet plant start to work, there are many factors that may impact the efficiency of the pellet plant. For example: the types of raw materials, the moisture of raw materials, the drying performance, etc. The engineers will give the pellet plant workers a proper training about the usage of the wood chipper, hammer mill, pellet dryer, pellet mill, pellet cooler, the packing machine and other assistant equipment. As a professional pellet plant solution provider, the long term cooperation is what we value the most, in that case, even the pellet plant has been operated for quite a time, you can still reach Gemco to get the operation advise.