What is Pellet Plant Process Flow Chart?

To answer the question of what is pellet plant process flow chart, we have to figure out the phrase of flow chart. Flow chart is normally a type of diagram which shows the complete work flow of the things you want to know. So as you can see, the pellet plant process flow chart is a useful diagram which helps people to have an overall perspective of the pellet plant process.

Pellet Plant Process Flow Chart Types

From the general idea of pellet plant process flow chart, you can easily understand that the flow chart of pellet plant process is widely used in the designing and documenting the processes of the pellet plants. It is a necessary diagram for the complete pellet plant solutions.

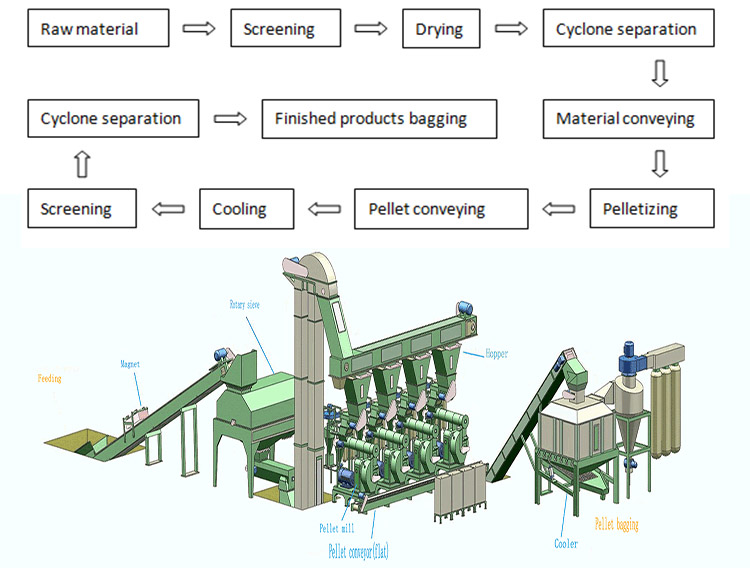

There are many different types of pellet plant process flow charts. The most simple flow chart of pellet plant process is the text-only version. This kind of pellet plant flow chart is the primary type which shows us the steps of a pellet plant. If you are interested in the wood pellet production industry or want to start a pellet plant of your own, the text-only version of pellet plant process flow chart will help you get a general idea about how many processes are there in a pellet plant and what are they. For the complete pellet plant solution providers, the text-only version of pellet plant process flow chart is the first diagram they offered to their clients, which is used to list the processes of the pellet plant they designed for their client.

Another kind of pellet plant process flow chart is the 3D type. The 3D pellet plant flow chart is also provided by the pellet plant solution providers. Unlike the text-only version, 3D pellet plant flow chart shows the customized pellet plant design. This type of pellet plant flow chart is used to determine the real pellet plant construction project.

Pellet Plant Processes

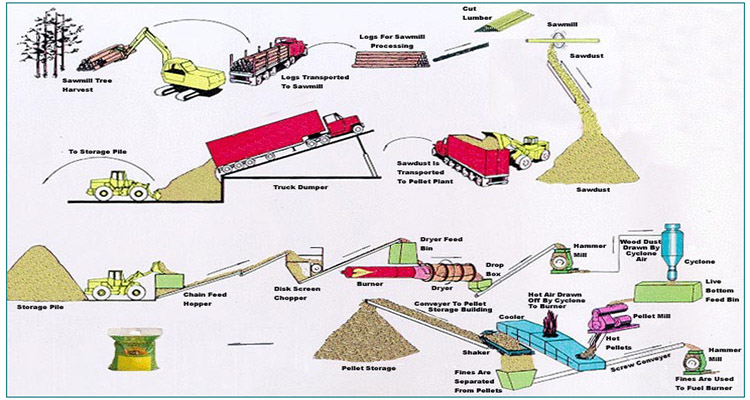

Generally, pellet plant process flow chart is the list of the pellet plant processes. To give you a better knowledge about what the pellet plant processes are, here we give you the processes of a standard wood pellet plant.

Raw materials storage

The first thing for a pellet plant is to have a place or warehouse to storage the raw materials. The materials for a pellet plant might be different, such as saw dust, wood chips, corn stalks, rice husk, sugarcane bagasse and so on. But, as the pellet mill technology requires a strict moisture content of the raw materials, the warehouse must have moisture-resistant feature.

Initial size reduction

The process is used to reduce the size of the bigger raw materials such as logs. From the word “ initial ”, we can easily find out that this is just the first size reduction process of the pellet plant. During the process, we use the wood chipper to cut the big raw materials into smaller pieces with a diameter no more than 20mm for the following processes.

Drying

As the pelletizing technology asks for a strict moisture content of the raw materials, so the drying process is necessary for the pellet plants. During the process, the rotary pellet dryer is used to complete the process. It is the most cost effective choice among all kinds of pellet drying machines.

Grinding

This is the second size reduction process in a pellet plant. In order to improve the wood pellet quality and output and lower the energy consumption of the pellet mill, we use a hammer mill to grind the raw materials into small particles with a diameter less than 5mm. The smaller the raw materials are, the better wood pellet we make.

Pelletization

This is the process that pelletize the raw materials into wood pellet. For the large pellet plant, ring die pellet mill is the perfect choice to make wood pellets. Normally, a ring die pellet mill maintains the capacity of 1 – 2 ton/h, if you need a larger capacity of the pellet plant, you can just simply connect several ring die pellet mills together.

Cooling

This is the temperature reduction process of a pellet plant. The wood pellets remain a extremely high temperature when they are discharged from the pellet mill. The counter flow pellet cooler is used to cool down the wood pellet to make it regain the proper rigidity.

Sieving

This is the process which separate the fines from the well-made wood pellet. The high quality wood pellet has a strict limit about the fine particles, therefore, after the wood pellet has been made, we use the pellet screener to separate the fines from wood pellet products.

Packaging

This is the last process in a pellet plant. The majority of the wood pellet plant are built for its commercial purpose, so the wood pellet products must have a proper package. The automatic packing machine is used to package the wood pellet into different types of bags, such as the bulk bag and the retail bag.