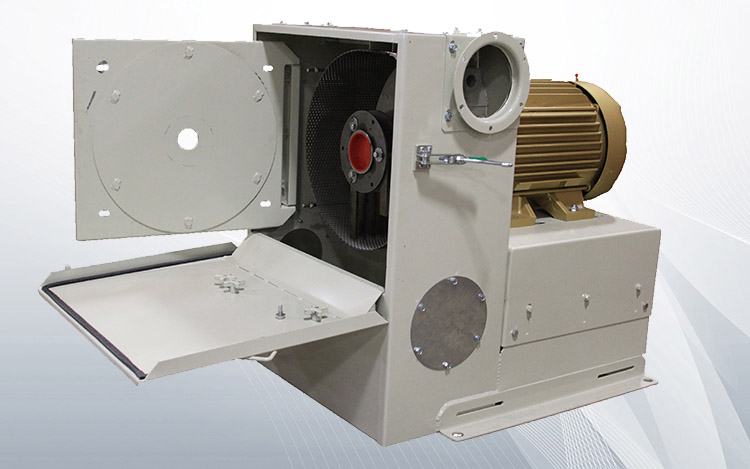

During the wood pellet manufacturing process of a pellet plant, hammer mill is one of the most important equipment in the complete wood pellet line. On one hand, the performance of the hammer mill is strongly impact the wood pellet quality, on the other hand, it also request a higher operating cost than most of the other equipment in a wood pellet plant. Therefore, as the main equipment of a pellet plant, when the hammer mill is in a mechanical failure, it will probably cause the unqualified product problem, or delay the routine working flow of a pellet plant. In the following article, Gemco has summarized the reason and solution of the hammer mill mechanical failure in wood pellet plant.

The Mechanical Failures of Hammer Mill in Pellet Plant

The Starting Difficulties of the Motor of Hammer Mill

The reason of starting difficulties of the motor of hammer mill

The power supply voltage of the motor is too low. Hammer mill is the main consumer of electric energy in the whole wood pellet production line, the power consumption of the hammer mill is about 1/3 of the total power consumption of the whole pellet plant. If the power supply voltage is too low, the start-up sound of the motor is low, when you hear the deep sounds when you start the motor, you must be careful, cause it may burn up the motor if you start the hammer mill in such circumstances.

Start the hammer mill with raw materials of wood pellet. Normally when you start the hammer mill, the chamber of the hammer mill should be clean, especially without raw materials, that would make the hammer mill easy to start. If there were raw materials in the chamber, and you try to start the hammer mill in force, it will burn up the motor because of the sudden power blackout or the post conveyor failures.

Start the hammer mill with load. Under normal circumstances, if you rotate the motor spindle manually, it should be flexible. But when the screw on the bearing bush is too tight, it may cause the deformation of the bearings, and increase the difficulties of the motor spindle rotation. So when you start the hammer mill, the resistive load increased, when it gets more serious, the bearing may be burned up.

The solution of starting difficulties of the motor of hammer mill

Check the power supply voltage before you start the hammer mill, avoid the peak time of electric demand. Or change for a suitable compensator. Or enhance the starting time of the hammer mill, and lowering the feed rate during the working period of the hammer mill.

Evacuate the raw materials in the hammer mill chamber.

Keep the wear-stress of screws on the bearings evenly.

The Violent Current Fluctuation of the Hammer Mill

The reason of the violent current fluctuation of the hammer mill

The uneven feeding rate. The evenly feeding rate can not only insure the quality of the wood pellet products, but also fully utilizing the performance of the hammer mill. When you feed too much materials in the hammer mill, it will cause the sudden increase of the motor load, which cause the violent current fluctuation of the hammer mill and may burn up the motor of the hammer mill.

Over high moisture content of the raw materials. If the moisture content of the raw materials is too high ( when the moisture content increased 1%, the electricity increased about 10% ), the screen mesh is easy to be blocked, which will definitely effect the discharge of the raw materials and cause the violent current fluctuation of the hammer mill.

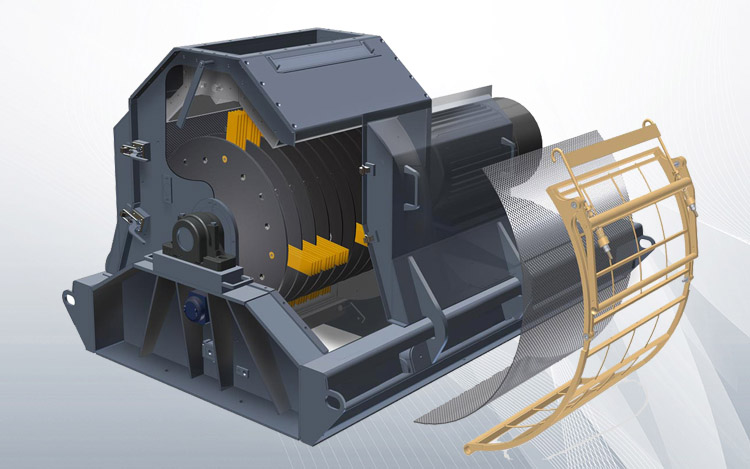

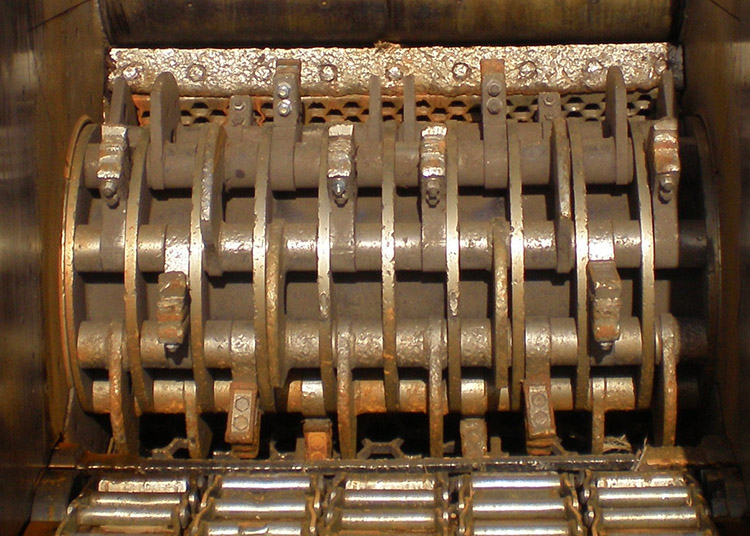

The wear problem of the hammers. The working principle of hammer mill is using the high speed rotary hammers installed in the crushing chamber to crush the raw materials. When the hammers are seriously wore, the crushing ability of the hammers will surely decrease. Also the wear problem of the hammer mill will make the bed of materials in the crushing chamber thicker, which will impact the discharge system, and cause the violent current fluctuation.

The feeding direction and the hammers rotary direction are not consistent. In the case of normal, the feeding direction and the rotary direction are the same, this is conducive to the crushing efficiency and the speed of the raw materials passing the screen mesh. But if the directions are not consistent, the time that the raw materials stays in the crushing chamber will increase, therefore the energy consumption is increased, and at the same time, it also cause the violent current fluctuation.

The stock guide does not throw down the materials along one side. If the stock guide is not in place, the raw materials will be fed into the crushing chamber by two parts, so the falling direction of the raw materials and the rotary direction of the hammers are not the same, which will cause the violent current fluctuation of hammer mill.

The influence of the negative pressure of the hammer mills. When the rotor of the hammer mill is rotating at a high speed, the hammer mill just like a fan, therefore there is negative pressure in the crushing chamber ( sometimes it could reach to more than 1.373 Pa ), but there is also little positive pressure on the screen. This will make the pressure difference of the two sides of the screen small, this is not good for the raw materials passing the screen. When the negative pressure of the hammer mill is small, or even back-jet, the capacity of the hammer mill is declined and cause the violent current fluctuation of the hammer mill.

The solution of the violent current fluctuation of the hammer mill

Use the automatic feeding method, such as the negative pressure feeding method. The manual feeding method is not recommended. Or you can use the advanced feeding machine and the frequency modulator to make the raw materials evenly entered the crushing chamber of the hammer mill.

Lowering the moisture content of the raw materials.

Change for the new hammers or reinstalled the hammer from the other side.

Check the feeding direction and the hammers rotary direction of the hammer mill.

Check whether if the stock guide of the hammer mill is in place.

Check the negative pressure system, make sure the negative pressure outside the crushing chamber is about 689 – 980 Pa.

The Uneven Particle Size

The reason of the uneven particle size

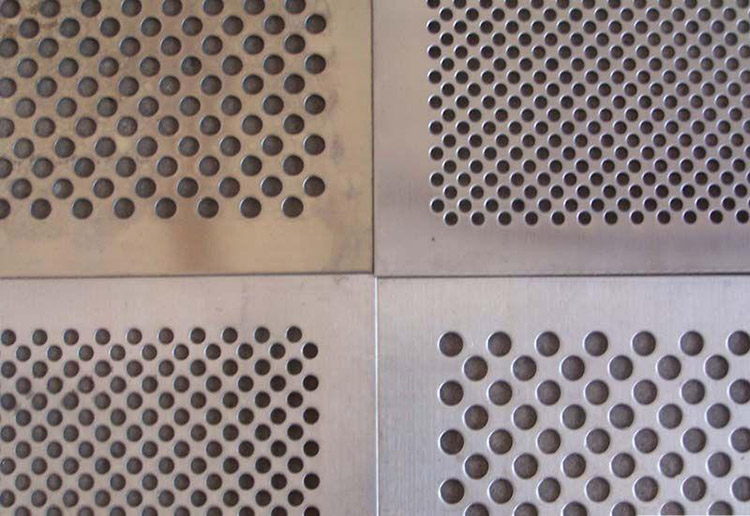

High moisture content of the raw materials. For hammer mills, it is mainly used the hammers that is rotating at a high speed to crush the raw materials persistently. It relies on the impact force that the hammers gives the raw materials. So, when the moisture content of the raw materials is low, the impact force makes the raw materials easy to crush. But when the moisture content of the raw materials is high, the crushed raw materials may not pass the screen mesh easily. And after the second crush in the crushing chamber, the particle size of the raw materials are smaller than the regular size.

The piercing problem of the screen mesh. If there are metal particles in the materials, and you did not sieve them out before fed them in the hammer mill, it is easy to make the screen mesh pierced by the metal particles under such a high rotary speed. Therefore, some of the raw materials will pass through the pierced hole, so the particle size is different from the regular size.

The sieve mesh is not in place. The production specification of sieve meshes are standardized. Normally, the sieve mesh is rectangular, but some unqualified sieve meshes may be parallelogram. So when you install the sieve mesh in the hammer mill, it couldn’t match the hammer mill exactly, and there will be some clearance between the sieve and the hammer mill, which caused the uneven particle size of the crushed materials.

The clearance of the broadsides of the sieve is too big. When you change the sieve mesh with different hole diameters, the tension of the sieve pressing spring must be adjusted due to the different thickness of the sieve meshes. When the tension of the springs can not press the sieve mesh tightly, there are part of the oversize materials passing through the broadsides of the sieve, which causes the uneven particle size.

The solution of the uneven particle size

Reduce the moisture content of the raw materials, and choose the sieve mesh with suitable hole diameters.

Change for a new sieve mesh, and install the magnetic separator.

Stop the hammer mill and change for a qualified sieve mesh.

Stop the hammer mill and check the clearance of the broadsides of the hammer mill sieve.

The Vibration Problem of Hammer Mill

The reason of the vibration problem of hammer mill

The wearing problem of hammers. When the hammers of the hammer mill are rotating at a high speed, the unbalanced weight of the hammers will generate a unbalanced centripetal force on the axis direction, which causes the vibration of the hammer mill.

The hammers do not rotate flexibly in the axle pin. When the hammers of the hammer mill are rotating at a high speed, and some of the hammers stick too tight, so it can not be swung during the operation. Therefore the vibration problem of the hammer mill occurs.

The clearance of the hammer mill bearings is over limits or broken. If the clearance of the hammer mill bearings is too big, when the hammers are rotating at a high speed, the axis will move axially, so that causes the vibration of the hammer mill.

The solution of the vibration problem of hammer mill

Reweigh the weight of each set of hammers, make sure the weight error of each set of hammers under 5g.

Stop the hammer mill and check the hammers manually, make sure the hammers can rotate flexibly.

Change for the new bearings.

The Decline of Production

The reason of the decline of production

The wearing problem of the hammers of hammer mill. If the hammers of the hammer mill are seriously wore, the crushing ability of hammers is also largely declined, and the bed of materials is thicker. These changes will definitely impact the discharge system, which causes the decline of production.

The influence of the negative pressure of the hammer mill. Keep the negative pressure of the hammer mill is aimed to make the large negative pressure under the sieve when the hammer mill is working, so that the crushed materials can quickly pass through the holes on the sieve to avoid the block problem of the sieve holes.

The solution of the decline of production

Change for the new hammers or reinstalled the hammer from the other side.

Clean the negative pressure air pipe, and check the negative pressure system.

Continue reading article within the same topic:

The Solution of Wood Pellet Plant False – Mechanical Failure of Wood Chipper

The Solution of Wood Pellet Plant False – Mechanical Failures of Pellet Mill