Running a wood pellet plant successfully needs a lot of efforts, such as the exact equipment that can suit your demands of wood pellet perfectly, the skilled workers, the reasonable management, and the ability of finding the mechanical false of the wood pellet plant and providing the solution of the wood pellet plant false.

As we all know, even though the best quality pellet equipment may have a mechanical failure. This is not because of the bad quality of the pellet machines, but caused by the wrong operation, such as the wrong materials, the lack of maintenance, and so on. As a top pellet plant solution provider in China, Gemco engineers have examined many different types of mechanical failures of the wood pellet plants, to find out the reasons that cause the wood pellet plant false and the solution of the wood pellet false. Hopes that it could help the wood pellet plant owners run their pellet plants more successful.

The mechanical failures of pellet plants are mainly caused by the wood pellet equipment in the pellet plant. Therefore, in this series of articles, Gemco has summarized the mechanical failures and solutions of the main equipment failures in the wood pellet plant. In the first part, let’s focus on the mechanical failures of wood chipper in pellet plant.

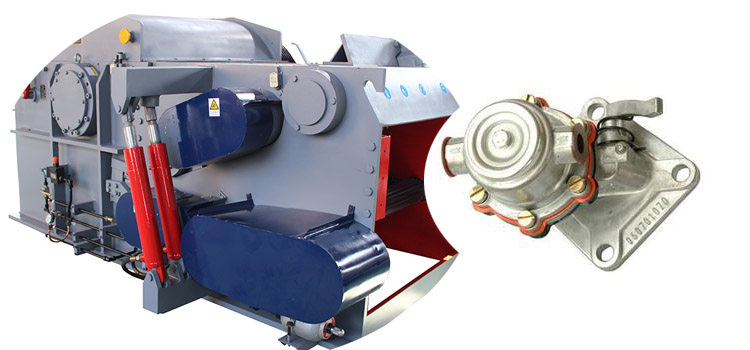

The Mechanical Failures of Wood Chipper in Pellet Plant

Great vibration of wood chipper

The reason of wood chipper vibration

The hydraulic system is out of oil, the wood chipper is running without oil.

The globe valve of the wood chipper hasn’t been turned off, and the handle of the manual fuel pump is on the position of oil return which makes the hydraulic system of wood chipper out of oil.

The oil pressure of the oil cylinder is not enough, the oil pressure is lower than the atmospheric pressure, so the energy accumulator doesn’t work.

The nitrogen pressure inside the energy accumulator is lower or higher than the required pressure, so the functions of energy storage and buffer are out of work.

The globe valve or the oil cylinder seals is damaged, so the oil pressure is not keepable.

The one-way throttle valve is fitted reversely which makes the feeding roller go down in a high speed.

The anchor bolt has not been fastened.

The discharge system is blocked.

The grinding quantity of the edges of the fly-cutters is not the same, or the weight of the fly-cutters is different.

The solution of wood chipper vibration

Feed the oil in the oil pump, and inject the regular oil pressure in the big oil cylinder.

During the working period of the wood chipper, the globe valve must be shut down, and the handle of the manual fuel pump must be put on the middle position.

Add the oil pressure, makes it just above the atmospheric pressure about 0.3 – 0.6 MPa.

Supplement or release part of the nitrogen, makes the nitrogen pressure meet the regular requirements.

Change the globe valve and the oil cylinder seals.

Reinstall the one-way throttle valve in the right direction.

Fasten the anchor bolt.

Remove the materials that cause the block of the discharge system, make sure that the discharged materials flow smoothly.

Exam the fly-cutters, and then regrind the blade or reweigh the fly-cutters.

The Unexpected Wood Chip Size

The reasons of unexpected wood chip size

If the wood chips that has been discharged from the wood chipper is in an unexpected size, then it is normally caused by the following reasons:

The space between the fly-cutters and the bedplate bar is too large.

Due to the wearing problem, the fly-cutter is blunt, or the cracks on the cutting edge is overmany.

The wearing problem of the bedplate bar.

The damage of the screen.

The length of the raw materials is too short.

The moisture content of the raw materials is lower than the regular requirements.

The solution of unexpected wood chip size

Adjust the space between the fly-cutter and the bedplate bar.

Replace the fly-cutter in whole set.

Replace the edge of the bedplate bar, or, regrind the edge of the bedplate bar.

Fix or replace the screen of the wood chipper.

Control the length of the raw materials, or feed the long raw materials and the short raw materials in a mixture way.

Soak the raw materials, the moisture content of the raw materials must be controlled under 40%.

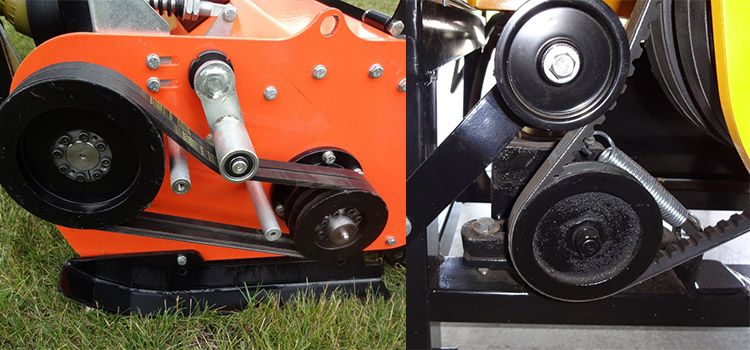

The Easy Wearing Problem of the V Belt

The reason of the easy wearing problem of the v belt

The v belt tension is not suitable:

- If the v belt is too loose, it can not transmit the power sufficiently, therefore, the wearing of the v belt increased.

- If the v belt is too tight, it will lead to the quick wearing and quick elongation of the v belt, which significantly shorten the serve life of the v belt.

The v belts in the same set have different length, which makes the v belts tensions are various in the same set, so the power that is transmitted by the v belts are not enough, and the v belt is therefore easy to wear.

If the feeding material is the wood branches with bark, it is difficult to be fed to the cutting position, which may cause the relative movement of the v belt and the branches, therefore the v belt may be tore up.

The solution of the easy wearing problem of the v belt

Adjust the tensity of the v belt.

Choose the v belt with the same length.

Debark the wood materials before feeding process, or keep the root of the branch forward when you feed it in the feed throat.

The Easy Wearing Problem of the Conveyor Belt

The reason of the easy wearing problem of the conveyor belt

The foundation under the driven roller of the conveyor assembly is the solid field, so the store of the broken wood chips may tear up the belt.

When you feed too many materials in the feeder, the wood chipper is overload, and there is not enough time to cut the materials, so the relative movement of the wood materials and the belt may tear the belt up.

If the feeding material is the wood branches with bark, it is difficult to be fed to the cutting position, which may cause the relative movement of the v belt and the branches, therefore the v belt may be tore up.

The solution of the easy wearing problem of the conveyor belt

Followed by the installation instruction of the wood chipper, open the discharge hole on the foundation, avoid the store of materials.

Feed the raw materials with required dimensions in the wood chipper.

Debark the wood materials before feeding process, or keep the root of the branch forward when you feed it in the feed throat.

The Fly-cutter Failure

The Reason of Fly-cutter Failure

The fly-cutter bolt or the bedplate bar bolt has not been fastened as the prescriptive fastening torque.

Use the plain bolt instead of the special fly-cutter bolt or the bedplate bar bolt.

The space between the fly-cutter and the bedplate bar is too small or there is no clearance between them.

The contact area of the fly-cutter holder and the bedplate bar holder is not fully cleaned, so the fly-cutter and the bedplate bar are not perfectly clumped.

The chuck has not been locked tightly.

There are metal comtaminant in the raw material which has been already fed in the wood chipper.

The utilization of poor quality blades.

The Solution of Fly-cutter Failure

Fasten the fly-cutter bolt and the bedplate bar bolt with the prescriptive fastening torque.

Order the high strength bolt from your equipment suppliers. Never use the plain bolt as a substitute.

Before you start the wood chipper, check the clearance between the fly-cutter and the bedplate bar by the thickness gauge, the regular clearance between them is 0.5 – 1mm.

When you change the cutters, the contact area of the fly-cutter holder and the bedplate bar holder must be perfectly cleaned.

Locked the chuck of the two sides.

Install a metal detector on the conveyor, exam the raw materials before they have been fed in the wood chipper.

Stop using the poor quality blade immediately, buy some new blade from the trusty manufacturers.

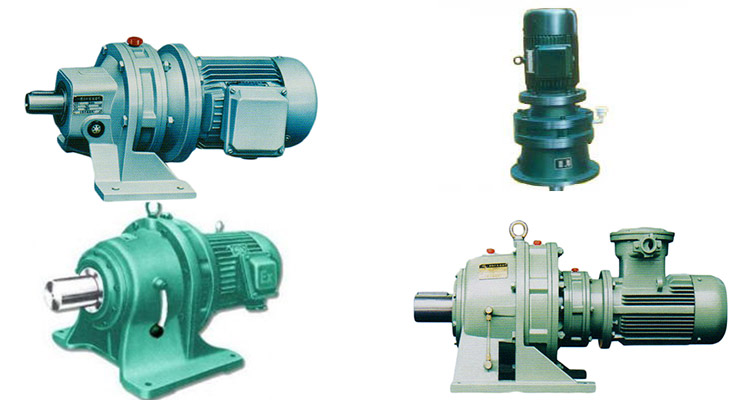

The Easy Wearing Problem of the Retarder

The reason of the easy wearing problem of the retarder

The feed rate is too high, which indicates a long term overload of the retarder of the wood chipper, so the gears are easy to wear.

The feed roller is deadlocked by the wood chips, but the retarder goes on running, which makes the gear damaged by overload.

The retarder has been shifted to rotate between forward and backward continually and directly, which makes the gears vulnerable.

The fuel load of the retarder is too much or too little.

The solution of the easy wearing problem of the retarder

Feed the raw materials with required dimensions in the wood chipper.

Clear the fines between the feed rollers and between the feed roller and the wall of the wood chipper.

Lower the feed rates, avoid the continually shift of the direction of rotation. Moreover, the direction of rotation mustn’t be shifted directly, you must fully stop the retarder and then shift the direction of rotation of the retarder.

Supplement or release the fuel load of the retarder.

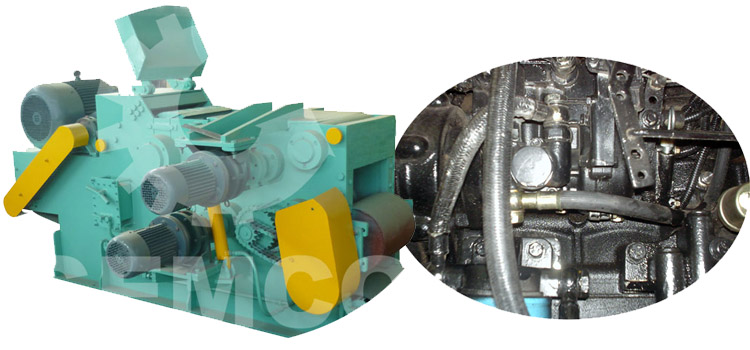

The oil pump failure

The reason of the oil pump failure

There is no oil in the oil pump.

The fuel inlet strainer mesh is blocked.

The steel ball of the oil outlet bush went missing (BX216, BX218).

The wearing problem of the seals on the piston (BX216, BX218).

The solution of the oil pump failure

Filled the manual fuel pump to reach the 3/4 of the height of the pump.

Clean the oil pump, and change the hydraulic oil.

Supplement the steel bar.

Change the seals on the piston.

The Over Heat Problem of the bearings

The reason of over heat problem of the bearing

The tapered adapter sleeve is too tight, so the fit clearance of the bearings is too small.

Too much grease on the gear.

The bearing house is not properly aligned.

The oil starvation and wearing problem of the bearing.

The solution of over heat problem of the bearing

Unscrew the tapered adapter sleeve to insure the fit clearance of the bearings.

Remove part of the grease.

Revise the concentricity of the bearing house.

Supplement the grease, or change the bearings.

Continue reading article within the same topic:

The Solution of Wood Pellet Plant False – Mechanical Failure of Hammer Mill

The Solution of Wood Pellet Plant False – Mechanical Failures of Pellet Mill