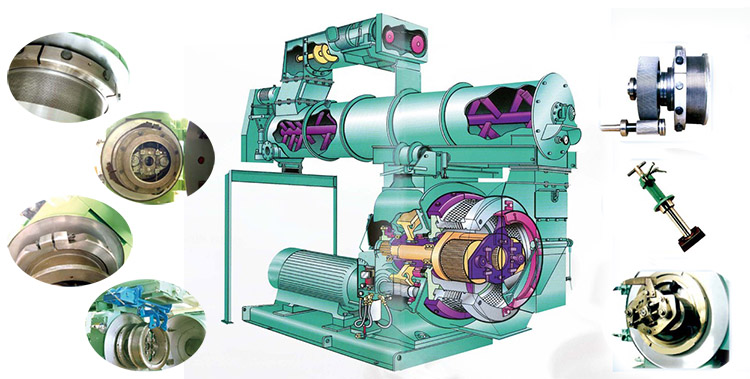

There is no doubt that the ring die pellet mill is the most important equipment in the biomass pellet plants. It is the step in the pellet plant which pelletized the processed raw materials into actual pellets. Therefore, the mechanical failures of the ring die pellet mill is definitely impact the production capacity of the pellet plants. As a professional pellet plant solution provider, Gemco is not only going to show you the reasons and solutions of the mechanical failures of the pellet mill in the pellet plants, but also the maintenance of the ring die pellet mill. Hope it could help you rule out the pellet mill false in your pellet plants.

The Mechanical Failures of Pellet Mill

The Decline of Pellet Mill Production

The reasons caused the decline of pellet mill production

It is the first time of using the ring die, so the smoothness of the die holes are bad.

The moisture content of the raw materials is either too high or too low.

The clearance of the rollers and the ring die is too big.

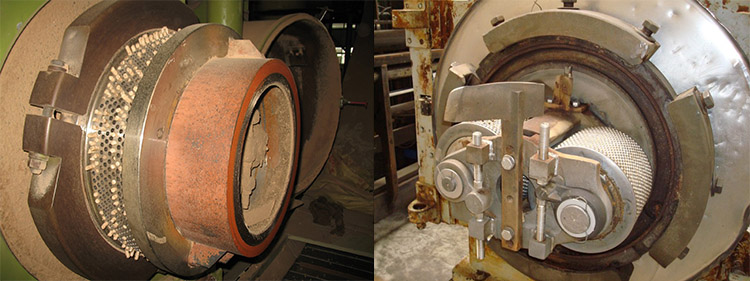

The rollers or the ring die is seriously wore.

The solutions of the decline of pellet mill production

Use the oil fuel to grind in the pellet mill before the actual pellet production in order to lubricate the ring die.

Control the moisture content of the raw materials. For industrial pellet plants, the drying process in needed.

Adjust the clearance between the rollers and the ring die of your pellet mills.

Change for new rollers or ring die of the pellet mill.

The Excessive Fine Content of the Wood Pellet

The reasons caused the excessive fine content of the wood pellet

The moisture content of the raw materials that has been fed in the pellet mill is too low.

The over wearing problem of the ring die of the pellet mill, which makes the compression ratio of the wood pellet declined.

The solutions of the excessive fine content of the wood pellet

Enhance the moisture content of the processed raw materials.

Change for the new ring die of the pellet mill.

The Rough Surface of the Wood Pellet

The reasons caused the rough surface of the wood pellet

The moisture content of the raw materials that has been fed in the pellet mill is too high.

The first use of the ring die of the pellet mill will cause the rough surface problem of the wood pellet products.

The solutions of the rough surface of the wood pellet

Decrease the moisture content of the processed raw materials.

Enhance the times of grinding of the pellet mill by the oil fuel before the actual pellet production.

The Unusual Noise of the Pellet Mill

The reasons caused the unusual noise of the pellet mill

There are some solid contaminants mixed in the raw material, and have been fed into the pellet mill.

The bearing parts of the pellet mill are damaged.

The spare parts of the pellet mill is a little bit loose.

The usage of low quality bearing oil. The bearing oil is mixed with contaminants which damages the bearing of the pellet mill.

The solutions of the unusual noise of the pellet mill

Stop the pellet mill and clean the solid contaminants in the pellet mill.

Change for a new bearing of the pellet mill.

Fasten the loose spare parts of the pellet mill.

Check out the bearing parts of the pellet mill or contact your pellet mill manufacturer directly.

The Sudden Stop of the Pellet Mill

The reasons caused the sudden stop of the pellet mill

The pellet mill is over load, or even blow the fuse of the pellet mill.

There are some contaminants which has been mixed into the pellet mill chamber.

The voltage is too low, or the actual power of the pellet mill motor is small.

The solutions of the sudden stop of the pellet mill

Enhance the clearance between the pellet mill rollers and the ring die. If the fuse is blew out, change for a new fuse.

Stop the pellet mill and then clean the contaminants in the pellet mill.

Change for a new power line or a new motor.

The Unmoving Pressure Gage Hands of the Grease Pump or No Indicator Light

The reasons caused the unmoving pressure gage hands of the grease pump or no indicator light

The pellet mill pressure gage or the indicator light on the pellet mill is broken.

The piston cavity of the pellet mill has been mixed in some contaminants or air.

The solutions of the unmoving pressure gage hands of the grease pump or no indicator light

Change for a new pressure gage or indicator light of the pellet mill.

Take part the exposed joints of the cavity, cleaned each spare parts inside the joints one by one, and than reset all the joints.

The Maintenance of Ring Die Pellet Mill

The above contents shows you what to do when there is something wrong with the ring die pellet mill. But how to maintain the ring die pellet mill away from out of working is more important for the wood pellet manufacturers. So as the complete pellet plant solutions provider, Gemco will talk about the maintenance of ring die pellet mill in the following paragraphs.

The Routine Maintenance

Every lubricating points of the pellet mill should be oiled by each shift of workers. The pellet mill rollers should be cleaned once a week and be fed in the high temperature lubricating oil.

Before each shift of workers starts to work, the clearance between the knife and the ring die should be checked. The clearance must be no less than 3mm.

Before each shift of workers starts to work, the workers must check every screw and scraper in the pellet mill chamber one by one, see if the screw and scraper are loose.

Check the clearance between the rollers before you start the pellet mill, make sure the clearance between two rollers are the same.

Be aware of the leakage phenomenon of the pellet mill, and change the oil seal immediately.

Keep the surface of the pellet mill clean.

Continue reading article within the same topic:

The Solution of Wood Pellet Plant False – Mechanical Failure of Wood Chipper

The Solution of Wood Pellet Plant False – Mechanical Failure of Hammer Mill